1. ASTM A106 GR.B Carbon Steel Tube Chemical Composition

A106 GR.B carbon steel exhibits the following chemical properties, which contribute to its durability and performance:

Carbon (C): ≤0.30% (ensures weldability and reduces hardening risks).

Manganese (Mn): 0.29–1.06% (enhances strength and toughness).

Silicon (Si): ≥0.10% (improves deoxidation and high-temperature stability).

Phosphorus (P) and Sulfur (S): ≤0.035% each (minimizes impurities to enhance corrosion resistance and mechanical integrity).

Other Elements: Limited amounts of chromium, copper, nickel, and molybdenum to further optimize performance.

2. ASTM A106 GR.B Carbon Steel Tube Mechanical Properties

Tensile Strength: ≥415 MPa.

Yield Strength: ≥240 MPa.

Elongation: ≥30% (indicating good ductility and resistance to deformation under stress).

3. ASTM A106 GR.B Carbon Steel Fin TubeTemperature and Pressure Tolerance

Operating Temperature Range: -29°C to 565°C (suitable for both low and high-temperature applications).

Pressure Handling: Capable of withstanding high-pressure environments, making it ideal for boilers and heat exchangers.

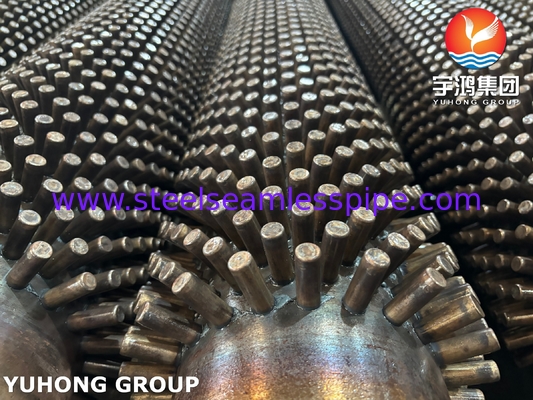

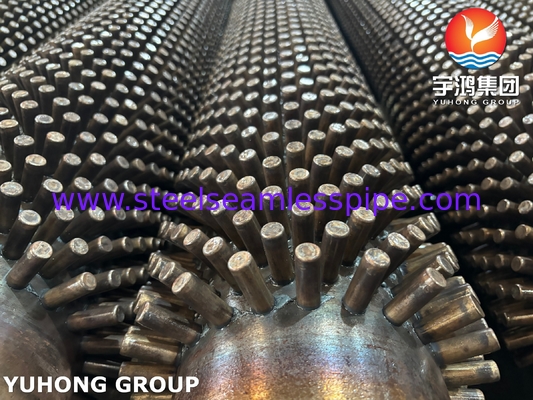

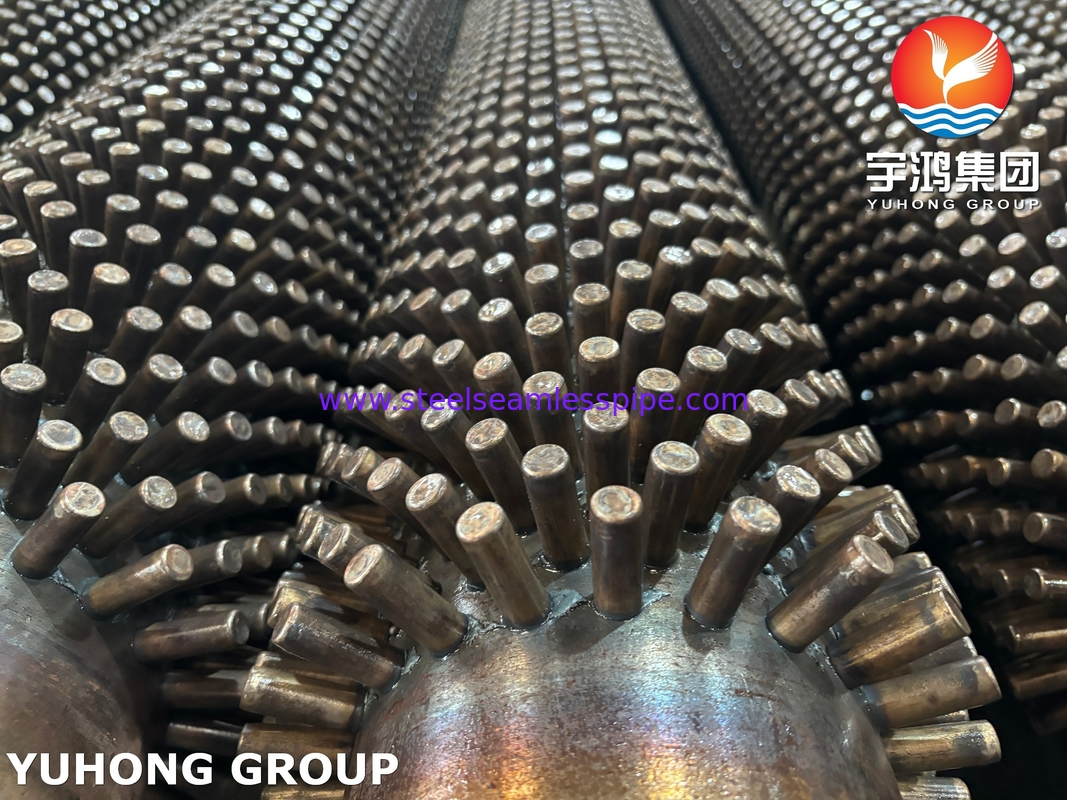

- Design and Features of Studded Fin Tubes

Studded Fin Design: These are radial or helical studs welded onto the outer surface of the base tube. This design significantly increases the heat transfer surface area, improving thermal efficiency in applications such as heat recovery systems and boilers28.

Customization: Fins can be tailored in terms of density, height, and pattern to meet specific thermal and mechanical requirements9.

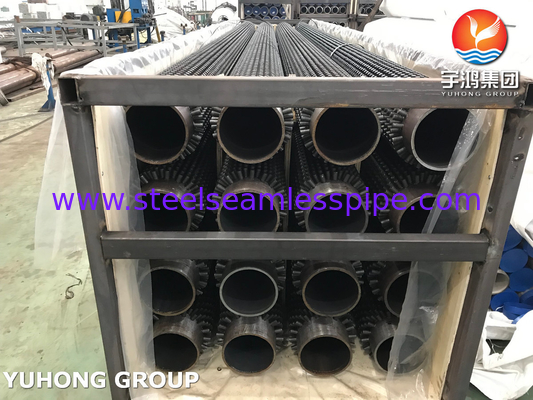

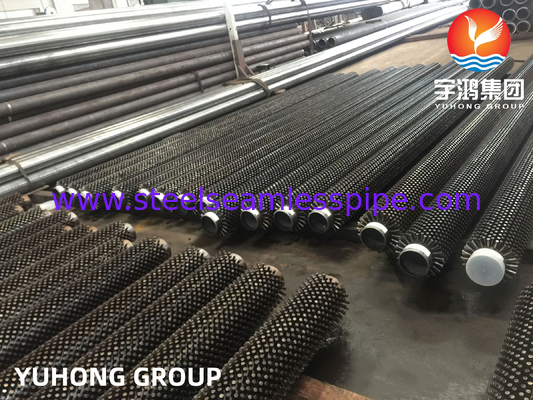

Base Tube: Made from seamless A106 GR.B carbon steel, ensuring uniformity and strength.

Fin Attachment: Studs are attached through resistance welding or high-frequency welding techniques, ensuring minimal thermal distortion and strong bonds.

4. Applications of A106 GR.B Studded Fin Tubes

Boilers: Used in high-pressure boilers for power plants and industrial heating systems due to their ability to withstand extreme temperatures and pressures.

Heat Exchangers: Ideal for petrochemical and chemical processing industries where efficient heat transfer is critical.

Power Generation: Employed in fossil fuel and nuclear power plants for economizers, superheaters, and other heat exchange components.

5. Advantages of A106 GR.B Studded Fin Tubes

Enhanced Heat Transfer: The studded fins increase surface area, improving thermal efficiency.

Durability: The base material’s high tensile and yield strength ensure longevity even under cyclic thermal stresses.

Corrosion Resistance: Low phosphorus and sulfur content reduce susceptibility to corrosion.

Ease of Welding and Fabrication: Low carbon content simplifies welding and fabrication processes without the need for pre- or post-weld heat treatments.

6. Comparison with Other Materials

While A106 GR.B is often compared to GB/T 8163 20# steel, it offers superior low-temperature performance (down to -29°C) due to its higher manganese content, making it more versatile for critical applications.

7. Summary

A106 GR.B carbon steel studded fin tubes are robust, efficient solutions for high-temperature and high-pressure heat transfer applications. Their excellent mechanical properties, combined with the enhanced surface area from studded fins, make them indispensable in industries like power generation, petrochemicals, and boiler manufacturing. When procuring these components, prioritize suppliers who adhere to ASTM standards and offer customization to meet specific operational needs.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!