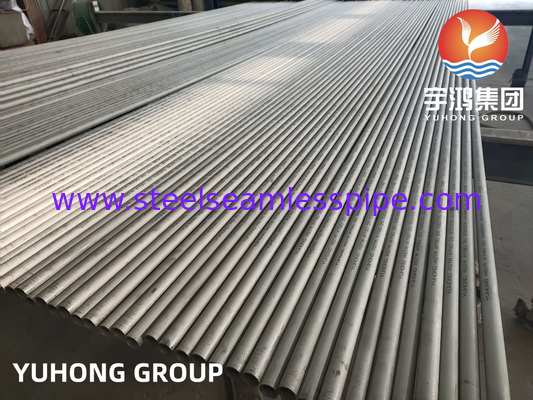

- YUHONG brand goods have been already exported to more than 85 countries With more than 35 years' experience, because of strict quality control policy, excellent sales service, delivery on time. YUHONG won more and more new clients and got more and more repeat orders from old clients, in YUHONG People's mind: Quality is First Important!

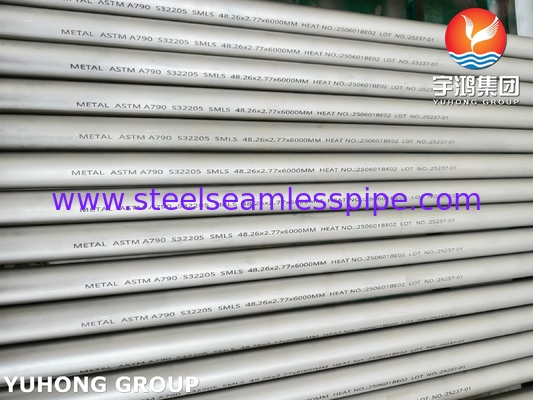

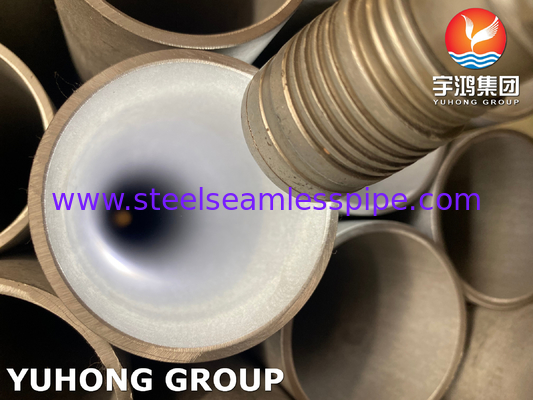

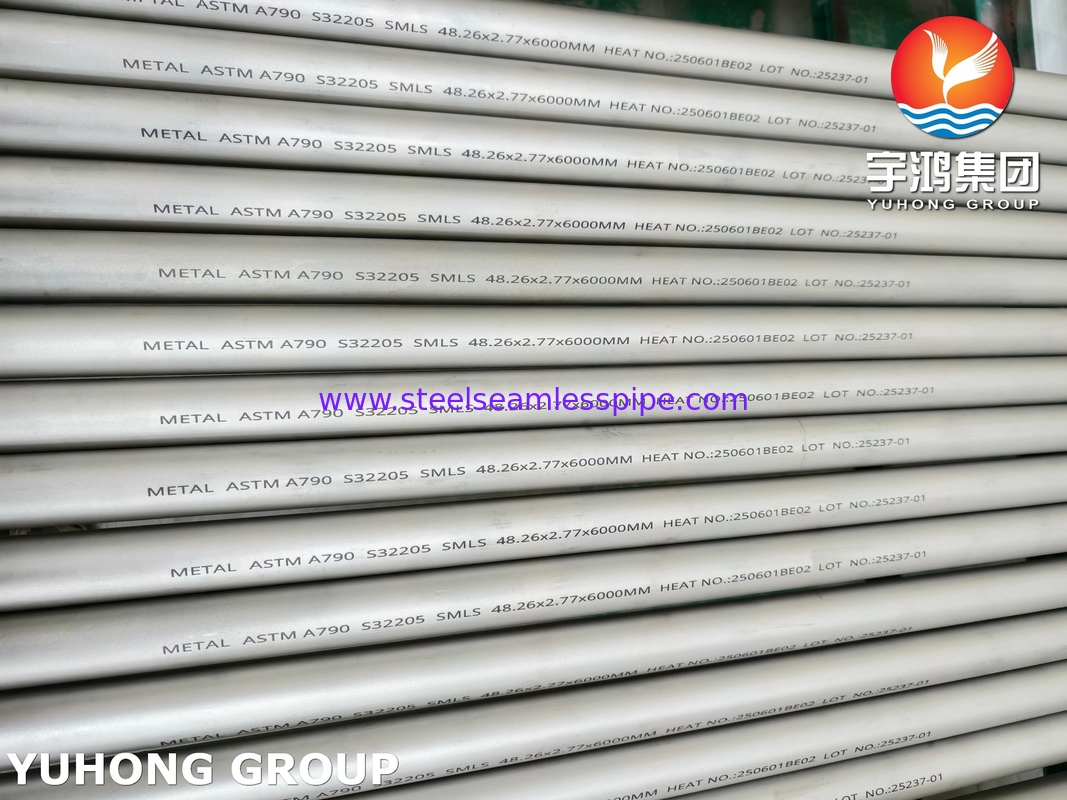

ASTM A790 UNS S32205 Seamless and Welded Duplex Stainless Steel Pipe

ASTM A790/ASME SA790 is a standard specification for seamless and welded ferritic/austenitic (duplex) stainless steel pipe, with particular emphasis on resistance to stress corrosion cracking. These steels are susceptible to embrittlement if used for prolonged periods at elevated temperatures. The UNS S32205 designation specifies the exact chemical composition and mechanical properties, representing the most common and standardized grade of duplex stainless steel. This pipe combines excellent stress corrosion cracking resistance, high strength, and good ductility, making it suitable for a wide range of demanding environments in oil & gas, chemical processing, and offshore applications.

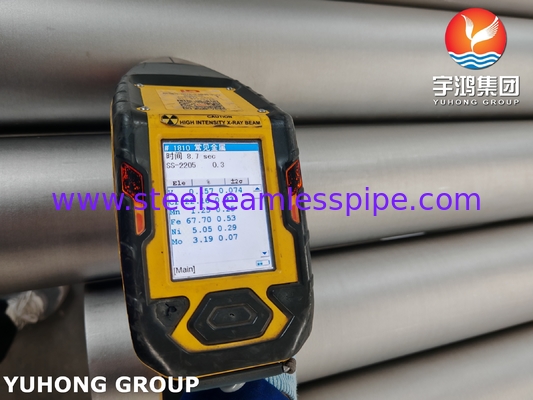

1.Chemical & Mechanical Properties

| ASTM A790 UNS S32205 Chemical Composition (%) |

| C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

N |

| ≤ 0.030% |

≤ 2.00% |

≤ 0.030% |

≤ 0.020% |

≤ 1.00% |

22.0 - 23.0% |

4.5 - 6.5% |

3 - 3.5% |

0.14 - 0.20% |

Mechanical Properties

| Property |

Standard Value |

| Tensile Strength |

655 MPa |

| Yield Strength (0.2% offset) |

≥ 450 MPa |

| Elongation |

≥ 25% |

| Hardness |

≤ 290 HRW/ 30HRC |

| Heat Treating Temperature |

1870-2010°F [1020-1100°C] |

2. Key Adventages

- Exceptional Strength and Lightweight Design

Its yield strength (≥450 MPa) is more than double that of standard austenitic stainless steels (e.g., 304/316, ≥205 MPa) and even surpasses that of carbon steel. This allows engineers to reduce wall thickness for the same design pressure and mechanical requirements, significantly cutting material weight and cost. It is particularly advantageous for high-pressure systems, subsea pipelines, and applications where weight reduction is critical.

-

Superior Resistance to Chloride Stress Corrosion Cracking (SCC)

In chloride-containing environments (e.g., seawater, chemical processes, hot saline solutions), austenitic steels (304/316) are highly susceptible to Stress Corrosion Cracking. However, the duplex microstructure of S32205 grants it exceptionally high resistance to SCC. Its performance far exceeds that of 304/316 and, in some environments, rivals that of higher-alloy "super" stainless steels. This is one of its core advantages.

-

Good General Corrosion and Pitting/Crevice Corrosion Resistance

Thanks to its high content of Chromium (Cr), Molybdenum (Mo), and Nitrogen (N), S32205 offers excellent general corrosion resistance. Its Pitting Resistance Equivalent Number (PREN) is typically ≥35, far exceeding that of 316L (PREN ~25). This means it provides significantly stronger resistance to pitting and crevice corrosion in aggressive environments like acidic media, seawater, and chemical processes.

-

Excellent Resistance to Erosion-Corrosion and Corrosion Fatigue

Its high strength and inherent hardness make it more resistant to erosion-corrosion caused by solid particles in fluids. Furthermore, its high strength translates to superior corrosion fatigue resistance, which is critical for components subjected to cyclic loading, such as piping systems on offshore platforms and vibrating parts.

From a Life Cycle Cost (LCC) perspective, S32205 is highly competitive. Although its initial cost is higher than carbon steel and 304/316, its longer service life, lower maintenance costs, and potential savings in installation and design due to weight reduction often result in a lower total cost of ownership for demanding applications.

3. Key Applications

- Oil and Gas Industry

- Chemical Processing & Petrochemical Industry

- Marine & Offshore Engineering

- Energy & Environmental Protection

- Pulp & Paper Industry

4. Testing

| Corrosion Test |

Destructive / Mechanical Testing |

Radiography Testing |

| Chemical Analysis |

Reverse-bend and Re. flat tests |

Corrosion Testing |

|

Destructive / Mechanical Testing

|

Eddy Current Testing |

Micro Testing |

| Reverse-bend and Re. flat tests |

Hydrostatic Testing |

Macro Testing |

| Eddy Current Testing |

Air Under Pressure Test |

IGC Testing |

| Hydrostatic Testing |

Eddy Current Testing |

Ultrasonic testing |

| Visual Inspection |

O.P Testing |

Liquid Penetrate testing |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!