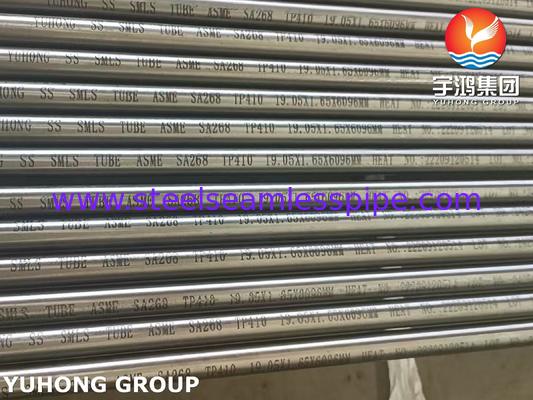

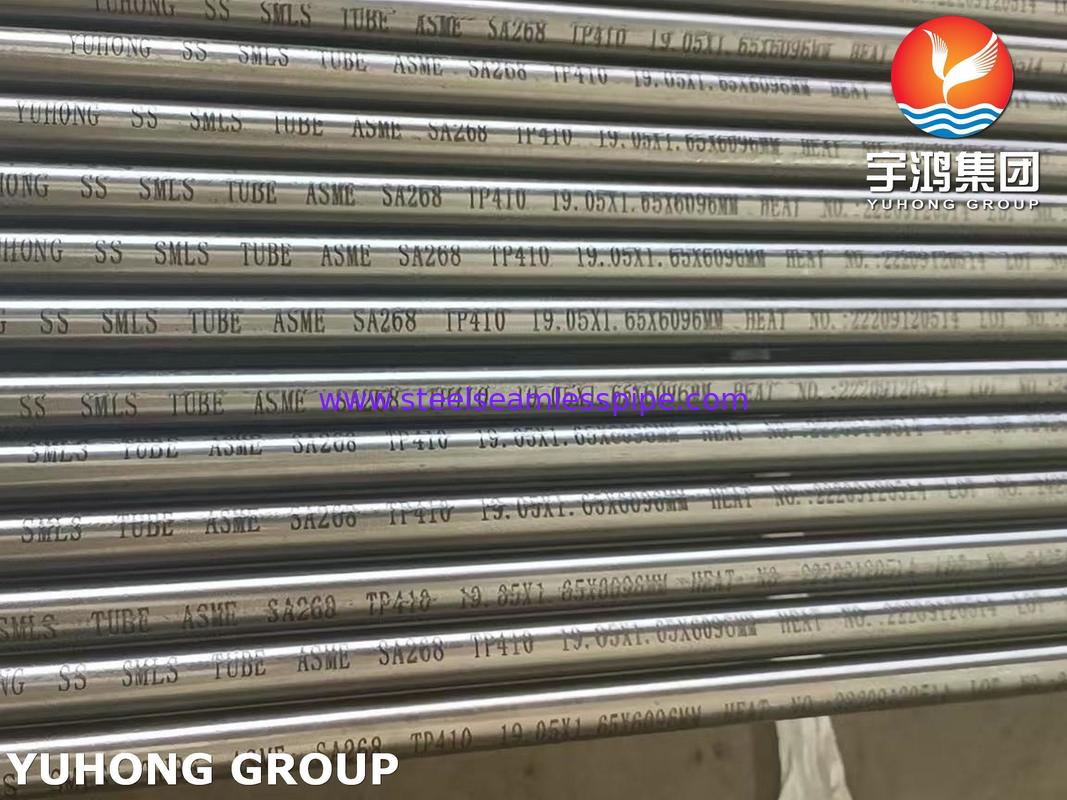

ASME SA268 TP410 Seamless Stainless Steel Tube

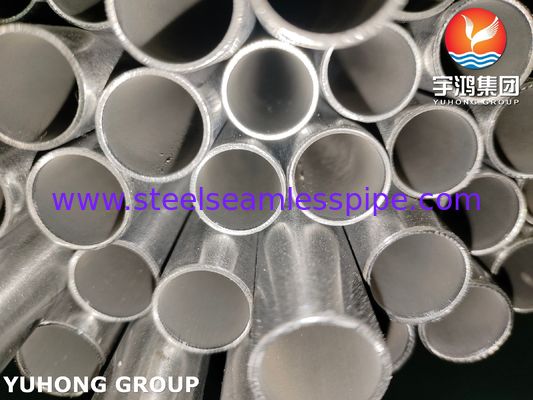

The ASME SA268 TP410 seamless stainless steel tube is a widely used martensitic grade known for its moderate corrosion resistance, high strength, and hardness. Manufactured via a seamless process, it ensures structural integrity for pressurized applications. This grade is typically supplied in heat-treated conditions—such as annealed or quenched and tempered—to achieve desired mechanical properties, making it suitable for a range of industrial uses including steam systems, oil well tubing, heat exchangers, and mechanical components.

TP410 is a basic martensitic chromium stainless steel containing approximately 11.5% chromium, which provides corrosion resistance in mild environments. Unlike austenitic grades such as 304 or 316, it is magnetic and can be strengthened through heat treatment. Its final properties are largely determined by its heat treatment condition.

Chemical Composition (%)

| Element |

C |

Mn |

Si |

P |

S |

Cr |

Ni (Optional) |

| Range |

≤ 0.15 |

≤ 1.00 |

≤ 1.00 |

≤ 0.040 |

≤ 0.030 |

11.5-13.5 |

≤ 0.60 |

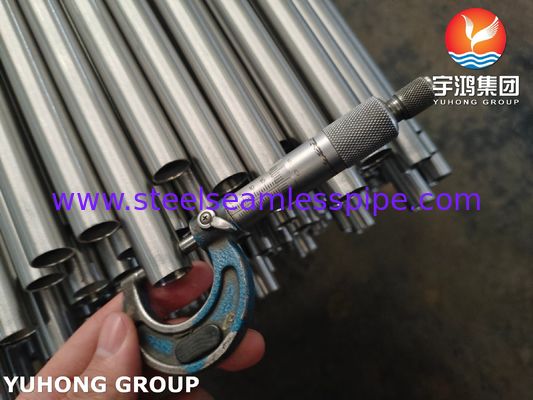

Mechanical Properties

| Tensile Strength |

Yield Strength (0.2% Offset) |

Elongation (% in 2 in) |

Hardness (Brinell) |

| ≥ 415 MPa |

≥ 205 MPa |

≥ 25% |

≤ 217 HB |

Note: Quenched and tempered TP410 can achieve significantly higher strength and hardness values.

Commonly Referenced Equivalent Materials

| ASTM/ASME |

UNS |

EN |

EN (Designation) |

JIS |

DIN |

| TP410 |

S41000 |

1.4006 |

X12Cr13 |

SUS 410 |

X10Cr13 |

Comparison: TP304 VS. TP410 VS. TP316

| Grade |

Key Characteristics |

Primary Application Guide |

| TP304 |

Excellent formability, good general corrosion resistance. |

The most common choice for general corrosive service (e.g., food, beverage, chemicals). |

| TP410 |

High strength & hardness; magnetic; moderate corrosion resistance. |

Selected for mechanical properties (wear, strength) in mild environments (e.g., steam, valves, cutlery). |

| TP316 |

Superior corrosion resistance, especially to chlorides and acids. |

The premium choice for aggressive environments (e.g., seawater, chemical processing, pulp & paper). |

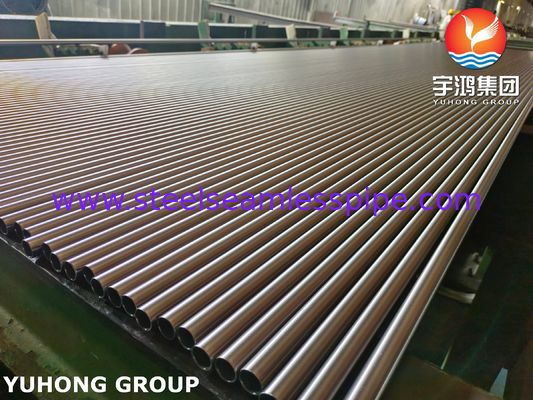

Apllication Of ASME SA268 TP410 Seamless Stainless Steel Tube

1. Power Generation: Low-pressure steam tubes, feedwater heaters, and steam condensate lines in mild service conditions.

2. Oil & Gas: Well tubing and flow lines for sweet (non-sour) production environments.

3. Heat Exchangers: Shell and tube heat exchangers for media like fresh water, oils, and organic chemicals.

4. Mechanical Components: Hydraulic cylinder tubes, bearing sleeves, bushings, and mandrels requiring wear resistance.

5. Automotive: Fuel injection lines and specific exhaust system components.

6. General Engineering: High-pressure process tubing and structural parts for machinery.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!