ASME SA209 Embedded Fin Tube with AL1060 Fin

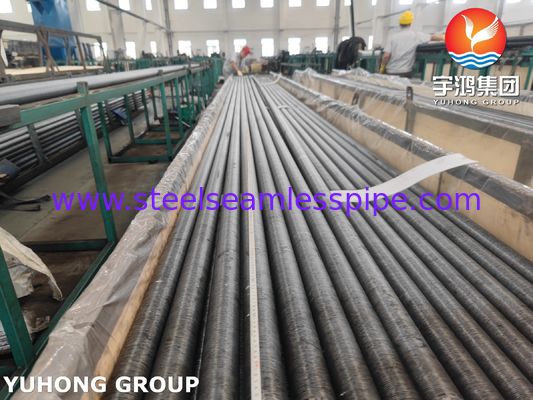

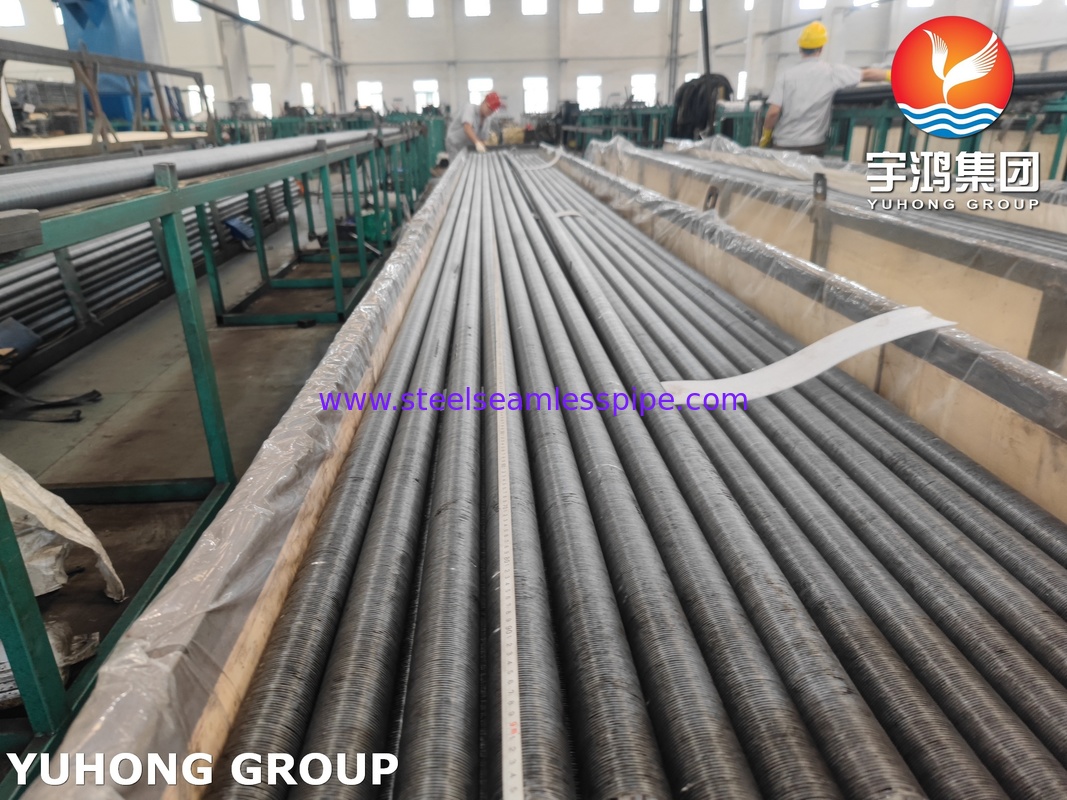

The ASME SA209 Embedded Fin Tube with AL1060 Fin is a highly efficient heat transfer component designed for applications where superior thermal conductivity and corrosion resistance are paramount in moderate temperature environments. It combines the robust mechanical properties and weldability of ASME SA209 steel base tube with the exceptional thermal performance and atmospheric resistance of mechanically embedded AL1060 aluminum fins. This configuration provides an optimal balance of performance, durability, and cost-effectiveness for various industrial heat exchangers.

Base Tube Material: ASME SA209

ASME SA209 is a specification for seamless carbon-molybdenum alloy-steel boiler and superheater tubes. The addition of molybdenum provides improved strength at elevated temperatures compared to carbon steel.

Key Alloying Element: Molybdenum (Mo). This element enhances the high-temperature strength and creep resistance of the steel.

Fin Material: AL1060 Aluminum

AL1060 is a commercially pure aluminum alloy (minimum 99.6% Al), known for its excellent thermal conductivity, formability, and outstanding resistance to atmospheric corrosion.

Chemical Composition (%)

ASME SA209 T1a Chemical Composition (%)

|

Element

|

C

|

Mn

|

P

|

S

|

Si

|

Mo

|

|

Range

|

≤0.18

|

0.30-0.80

|

≤0.025

|

≤0.025

|

0.10-0.50

|

0.44-0.65

|

AL1060 Chemical Composition (%)

|

Element

|

Al

|

Fe+Si

|

Cu

|

Mn

|

Mg

|

Zn

|

Ti

|

Others (Each)

|

Others (Total)

|

|

Range

|

≥99.60

|

≤0.35

|

≤0.05

|

≤0.03

|

≤0.03

|

≤0.05

|

≤0.03

|

≤0.03

|

≤0.10

|

Mechanical Properties

ASME SA209 T1a Base Tube Mechanical Properties

|

Tensile Strength

|

Yield Strength

|

Hardness

|

Elongation

|

|

≥380 MPa

|

≥205 MPa

|

-

|

≥30%

|

AL1060 Fin Mechanical Properties

|

Tensile Strength

|

Yield Strength

|

Hardness

|

Elongation

|

|

60 - 95 MPa

|

≥25 MPa

|

≤27 HB

|

≥15%

|

Advantages of ASME SA209 Embedded Fin Tube with Al1060 Fin

|

Property

|

Benefits

|

|

High Thermal Efficiency

|

The AL1060 aluminum fin provides excellent heat dissipation due to its high thermal conductivity (~200 W/m·K), significantly enhancing the overall heat transfer coefficient of the tube.

|

|

Corrosion Resistance

|

The AL1060 fin offers superior resistance to atmospheric corrosion, forming a protective oxide layer. The SA209 base tube provides resistance to various industrial environments and scaling.

|

|

Cost-Effectiveness

|

Aluminum fins on a steel tube offer a more economical solution compared to all-stainless or all-alloy finned tubes, providing excellent performance at a lower material cost.

|

|

Lightweight Fins

|

The use of aluminum for the fins reduces the overall weight of the heat exchanger assembly compared to heavier fin materials, which can simplify support structures and installation.

|

|

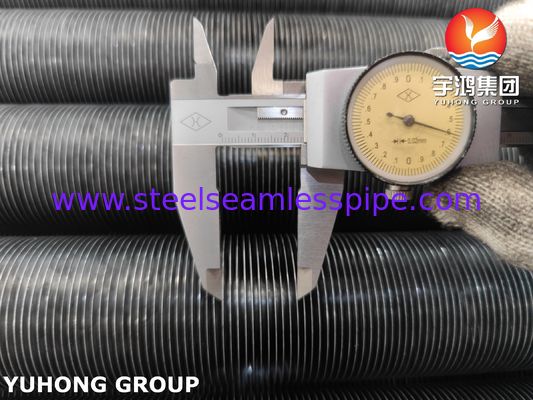

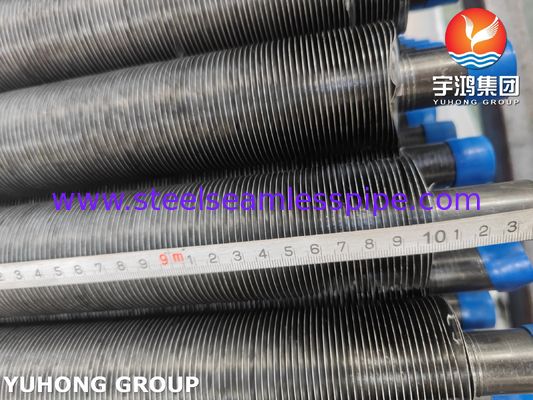

Robust Mechanical Bond

|

The embedded fin manufacturing process creates a strong, permanent mechanical bond between the fin and tube, ensuring structural integrity under thermal cycling and vibration.

|

|

Material Synergy

|

This combination optimally utilizes the strength and pressure containment of the steel base tube with the superior heat transfer and atmospheric corrosion resistance of the aluminum fin.

|

Applications Of ASME SA209 Embedded Fin Tube with AL1060 Fin

1. Heat Recovery Steam Generators (HRSG): Economizer and low-temperature evaporator sections where fine gases have cooled sufficiently to avoid overheating the aluminum fins.

2. Air-Cooled Heat Exchangers (ACHEs): Used as finned bundles in forced or induced draft fans for cooling process fluids, water, and lubricants in petrochemical and power plants.

3. Industrial Air Heaters: For heating combustion air or process air in furnaces and ovens, improving thermal efficiency.

4. Drying Ovens and HVAC Systems: As core heat transfer elements in industrial drying systems and large-scale heating, ventilation, and air conditioning units.

5. Energy Recovery Ventilators: Transferring energy between exhaust and fresh air streams in building climate control systems.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!