- YUHONG brand goods have been already exported to more than 85 countries With more than 35 years' experience, because of strict quality control policy, excellent sales service, delivery on time. YUHONG won more and more new clients and got more and more repeat orders from old clients, in YUHONG People's mind: Quality is First Important!

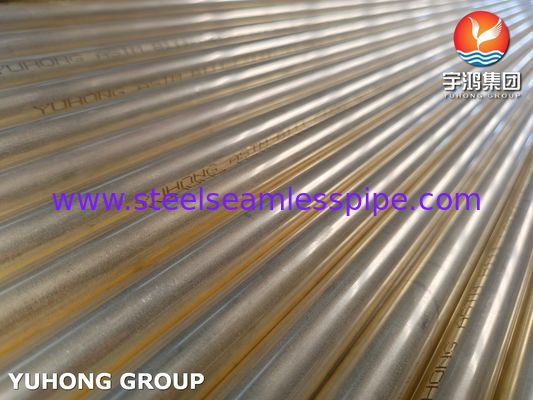

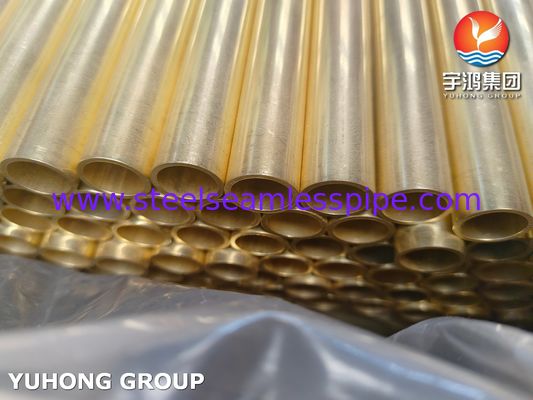

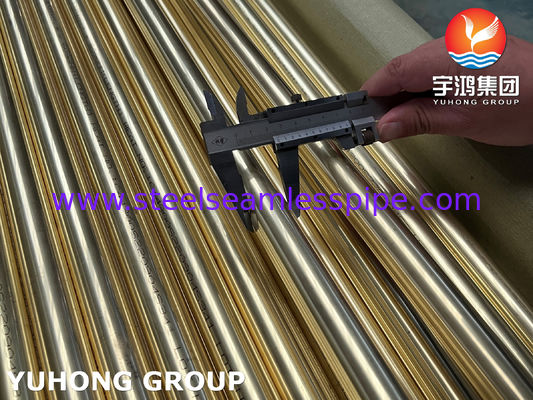

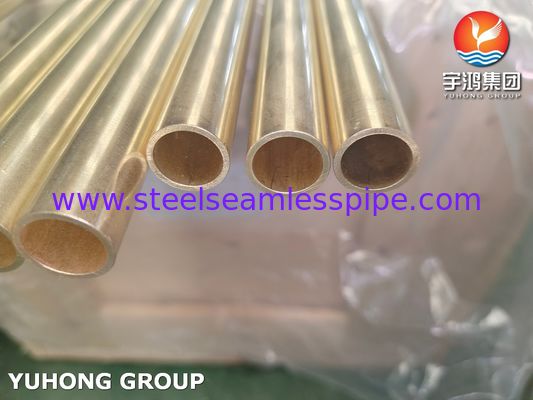

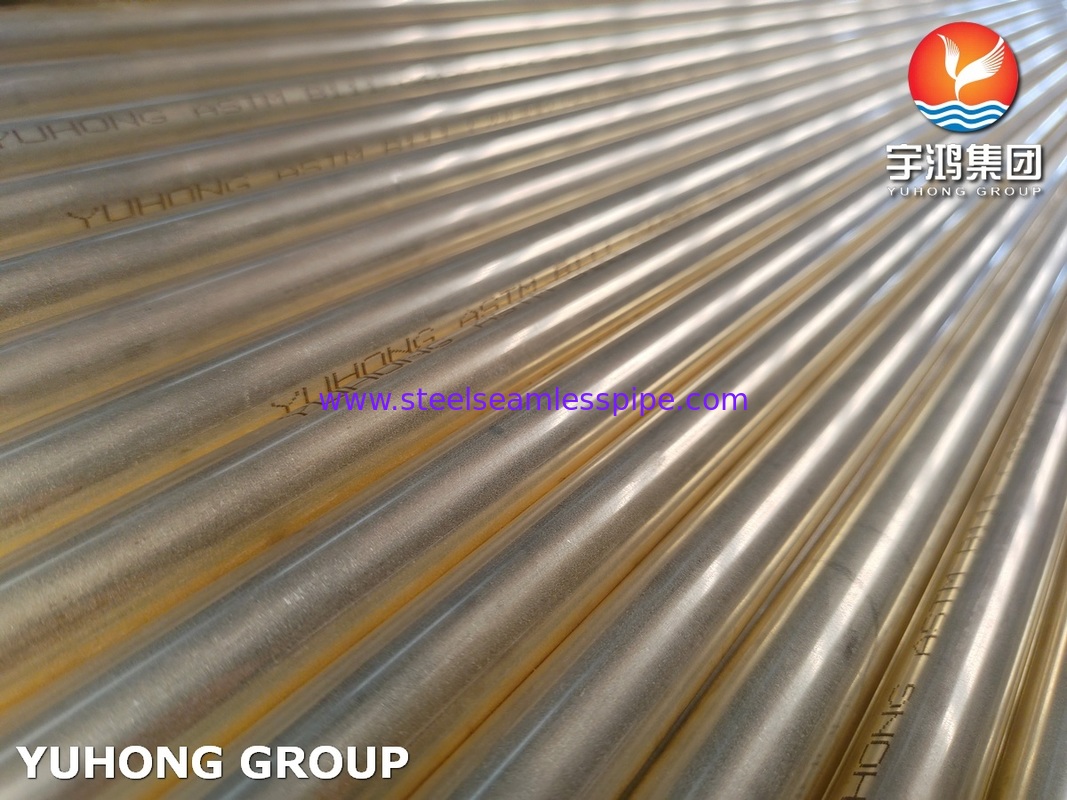

ASTM B111 C44300 O61 Annealed Copper-Alloy Seamless Tube, Harsh working conditions

ASTM B111 C44300 O61 Annealed Copper-Alloy Seamless Tube refer to seamless tube made from Admiralty Brass (C44300), manufactured in accordance with ASTM B111 standards and delivered in O61 annealed condition. This alloy is a copper-zinc alloy with a typical composition of approximately 71% copper, 28% zinc, and 1% tin, plus trace amounts of arsenic, antimony, or phosphorus to inhibit dezincification. Its most notable characteristic is exceptional resistance to seawater corrosion. The O61 annealing process provides high ductility and excellent workability, making these tubes widely used in condensers, heat exchangers, and marine piping systems for shipbuilding, power generation, and chemical processing industries.

1.Chemical & Mechanical Properties

| ASTM B111 C44300 Chemical Composition (%) |

| Cu |

Zn |

Ti |

Pb |

Fe |

As |

| 70.0-73.0% |

Rem |

0.9-1.2% |

≤0.07% |

≤0.06% |

0.02-0.06% |

Mechanical Properties

| Property |

Standard Value (Annealed) |

| Tensile Strength |

≥ 310 MPa |

| Yield Strength |

≥ 105 MPa |

| Thermal conductivity |

109 W/m-K @ 20.0 °C |

| Heat capacity |

0.09 cal/g-°C @ 20ºC |

| Density |

8.53 g/cc |

2. Key Adventages

- Exceptional Resistance to Seawater Corrosion

As "Admiralty Brass," its composition (with ~1% Tin and trace Arsenic/Antimony) effectively resists dezincification and impingement corrosion caused by seawater, making it an ideal choice for marine environments.

- Excellent Anti-Biofouling Properties

The release of copper ions provides natural antimicrobial and anti-fouling properties, effectively inhibiting the attachment and growth of marine organisms (e.g., barnacles, algae) on the pipe interior, reducing maintenance.

- Good Machinability and Formability

The O61 (Annealed) condition offers high plasticity and a soft microstructure, facilitating on-site operations such as bending, flaring, and flanging for easy installation.

- High Thermal Conductivity

It retains the inherent high thermal conductivity of copper alloys, enabling efficient heat transfer when used as heat exchanger tubes, thereby improving energy efficiency.

- Robust Seamless Structure

The seamless manufacturing process ensures structural continuity and uniformity in the circumferential direction, resulting in higher pressure-withstanding capability and reliability, with no risk of weld seam corrosion.

3. Key Applications

- Power Industry: Condensers, vacuum tubes, heat exchangers

- Shipbuilding and Marine Engineering: Seawater cooling pipes, piping systems, heat exchangers

- Chemical and Petrochemical Industry: Cooling water pipes in key locations

4. Test

- Pitting Tests

- Intergranular Corrosion Test

- Chemical Analysis

- Hardness Test

————————————————————————————————————————————————————————————————————

| Performance |

C44300

(Admiralty Brass)

|

C68700

(Arsenical Aluminum Brass)

|

C71500

(Cu-Ni 70/30)

|

C70600

(Cu-Ni 90/10)

|

| Composition |

Cu-Zn28-Sn1-As0.04 |

Cu-Zn20-Al1-As0.04 |

Cu-30Ni-0.7Fe |

Cu-10Ni-1.4Fe |

| Thermal Conductivity (W/m·K) |

110 |

100 |

29 |

50 |

| Seawater Corrosion Resistance |

★★★☆☆

(requires inhibitor)

|

★★★★★

(anti-dezincification)

|

★★★★★

(all-round)

|

★★★★☆

(better than 90/10)

|

| Acid Resistance |

★★☆☆☆ |

★★★☆☆ (pH≥6) |

★★★★★

(resists H₂S/CO₂)

|

★★★★☆ |

| Erosion-Corrosion Resistance |

★★☆☆☆ |

★★★★☆

(Al oxide layer)

|

★★★★★ |

★★★★☆ |

| Max Operating Temp(°C) |

150 |

200 (short-term 260) |

300 |

260 |

| Low-Temperature Toughness |

Good above -40°C |

Good above -40°C |

Stable at -196°C |

Stable at -100°C |

| Cost Index |

$$ (lowest) |

$$$ (moderate) |

$$$$$ (highest) |

$$$$ |

| Typical Applications |

Freshwater coolers, HVAC |

Seawater condensers, marine heat exchangers |

Offshore platforms, LNG equipment |

Desalination plants, chemical exchangers |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!