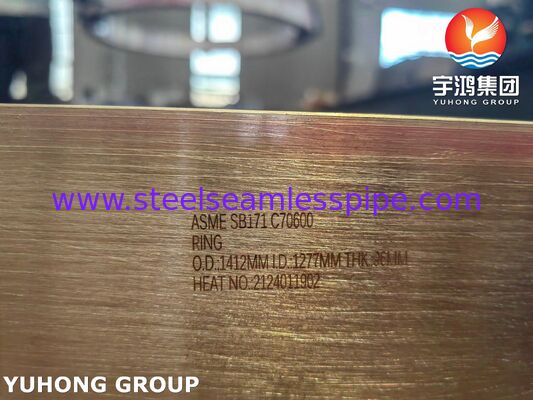

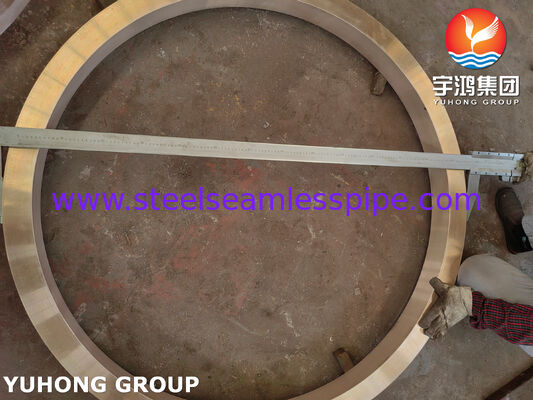

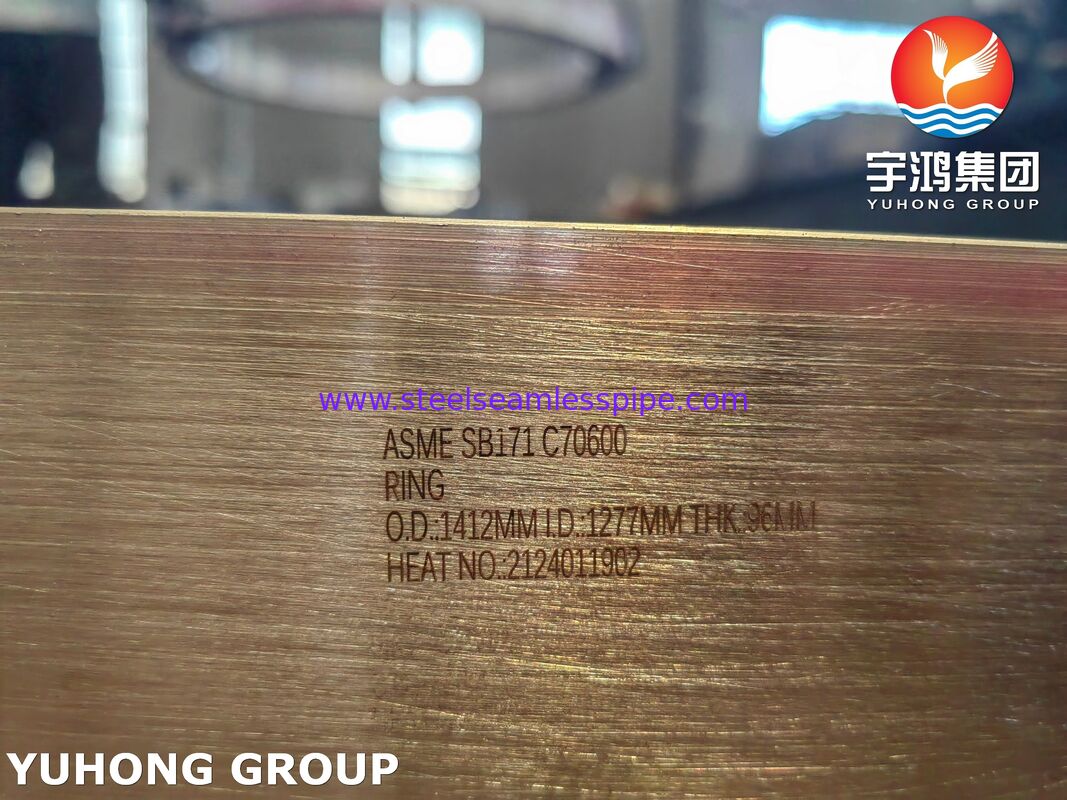

ASME SB171 C70600 Copper Nickel Alloy Ring For Heat Exchanger Part

ASME SB-171 C70600 (commonly referred to as 90/10 Copper-Nickel) is a critical alloy for demanding marine and industrial applications, primarily due to its exceptional corrosion resistance, especially in seawater.

When fabricated into a ring (likely a welded or forged ring shape), it is typically used as a flange-facing ring or a liner ring in piping systems. Here are the primary uses:

1. Primary Use: Seawater and Marine Systems

This is the most common and important application. C70600 rings are used in:

Shipbuilding & Offshore Platforms: For piping systems handling seawater for cooling, firefighting, ballast, and bilge services.

Desalination Plants: In multi-stage flash (MSF) and reverse osmosis (RO) plants where resistance to saltwater corrosion and biofouling is paramount.

Power Plants: Specifically coastal power stations that use seawater for condenser cooling.

Salwater Intake & Outfall Systems: For large diameter pipes and the associated flanged connections.

2. Specific Function: As a "Weld Ring" or "Liner Ring"

The ring form factor is key. It is often used in one of two ways:

Flange Facing / Liner Ring: A thin ring of C70600 is welded (often overlay welded or butt-welded) onto the facing of a carbon steel flange. This creates a corrosion-resistant sealing surface on an otherwise less expensive and stronger steel flange, providing a perfect seal with C70600 pipes or valves. This is a cost-effective alternative to making the entire flange from solid copper-nickel.

Pipe Liner Ring / Weld Prep Ring: Used in bimetallic or "clad" pipes, where a carbon steel pipe has a thin internal liner of C70600 for corrosion resistance. The rings are used at pipe ends to facilitate the welding and transition between the steel structural layer and the copper-nickel corrosion-resistant layer.

3. Other Key Applications

Heat Exchanger & Condenser Shells: As support rings or flange rings where the shell is in contact with seawater.

Chemical Processing: For handling acids, alkalis, and other corrosive fluids, though its use here is less common than in marine environments.

Oil & Gas Subsea Systems: In components exposed to seawater, such as manifold rings, jumper connectors, or splash zone protection.

Why Choose C70600 for These Applications?

Superior Seawater Corrosion Resistance: Excellent resistance to impingement attack, crevice corrosion, and stress-corrosion cracking.

Biofouling Resistance: Naturally inhibits the attachment of marine organisms like barnacles and mussels better than many other metals.

Good Fabricability & Weldability: Can be easily welded using appropriate techniques (e.g., TIG/MIG with matching filler metal).

ASME SB-171 Certification: This standard ensures the material meets strict chemical composition and mechanical property requirements for pressure vessel and boiler code construction, making it suitable for critical, code-regulated systems.

An ASME SB-171 C70600 Copper-Nickel Alloy Ring is primarily a corrosion-resistant component for flanged connections in seawater piping systems. It is most often used as a cost-effective, welded overlay or liner on carbon steel flanges and pipe ends to provide a durable, seawater-proof seal in ships, desalination plants, offshore platforms, and coastal power stations.

Chemical Composition of ASME SB171 C70600

| Chemical Composition % |

Cu |

Pb |

Zn |

Fe |

Ni |

Mn |

| Rem. |

0.02 |

0.5 |

1.0-1.8 |

9.0-11.0 |

1.0 |

Physical Property of ASME SB171 C70600

| Properties |

Metric |

Imperial |

| Density |

8.94 g/cm3 |

0.323 lb/in3 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!