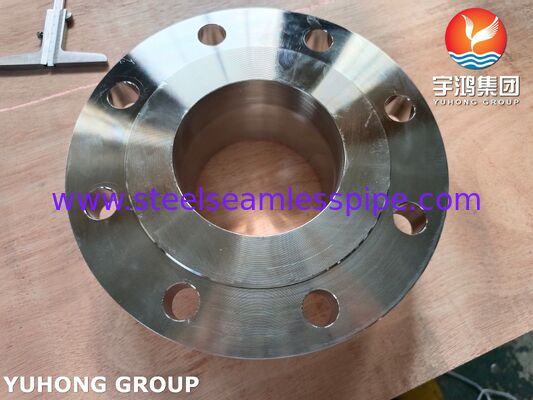

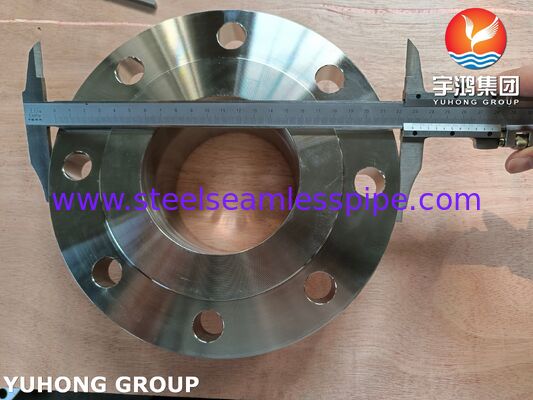

ASTM B462 N10276 Nickel Alloy Steel Flange for High Temperature

ASTM B462 is a material standard, officially titled "General Requirements for Forged or Rolled Nickel and Nickel Alloy Flanges, Forged Pipe Fittings, Valves and Components". It specifies the chemical composition, mechanical properties, and heat treatment requirements for nickel-based alloy materials used in the manufacture of pressure piping components such as flanges.

UNS N10276 is one of the most well-known and widely used alloys under this standard, with its common designation being Hastelloy C-276. It is a nickel-chromium-molybdenum-tungsten alloy, renowned for its excellent overall corrosion resistance.

ASTM B462 N10276 Nickel Alloy Steel Flange Chemical Composition

| UNS GRA. |

ASTM B462 N10276 Flange CHEMICAL COMPOSITION % MAXIMUM |

| C |

MN |

P |

S |

SI |

CR |

NI |

MO |

FE |

W |

| N10276 |

0.01 |

1.0 |

0.04 |

0.03 |

0.08 |

14.5-16.5 |

REM |

15.0-17.0 |

4.0-7.0 |

3.5-4.0 |

The carbon and silicon content in the ASTM B462 N10276 nickel-based alloy flange is controlled at extremely low levels. This minimizes the precipitation of harmful carbides and silicides in the weld heat-affected zone or during heat treatment, ensuring that the corrosion resistance after welding is almost identical to that of the base metal. Meanwhile, the high molybdenum content provides strong resistance to reducing media corrosion, chromium provides resistance to oxidizing media corrosion, and tungsten further enhances the alloy's strength and overall corrosion resistance.

ASTM B462 N10276 Nickel Alloy Steel Flange Core Advantages

The core advantage of ASTM B462 nickel-based alloy flanges lies in their exceptional corrosion resistance, exhibiting excellent resistance in both oxidizing and reducing media.

1.Resistance to chloride ion stress corrosion cracking: Extremely superior performance, virtually eliminating chloride-induced stress corrosion cracking, a fatal weakness of stainless steel and many other alloys.

2.Resistance to pitting and crevice corrosion: Performs exceptionally well in media containing halides (such as chloride and fluoride ions).

3.Resistance to highly corrosive media: Excellent resistance to various strong acids such as wet chlorine, hypochlorite, chlorine dioxide, sulfuric acid, hydrochloric acid, acetic acid, and phosphoric acid, as well as acidic media containing impurities.

ASTM B462 N10276 Alloy Steel Flange Mechanical Property Requirements

|

UNS GRA.

|

Tensile Strength,

min, ksi [MPa]

|

Yield Strength,

0.2 % Offset, min,

ksi (MPa)

|

Elongation in

2 in. or 50 mm or 4D,

min, %

|

| N10276 |

100[690] |

41[283]

|

40

|

ASTM B462 N10276 Nickel Alloy Steel Flange Main Application

-

Chemical Processing Industry: Reactors, heat exchangers, and piping systems in contact with highly corrosive chemicals.

-

Flue Gas Desulfurization Systems: Absorption towers, flues, dampers, and other areas in contact with acidic condensates and chlorides.

-

Oil and Gas Industry: Extraction and production equipment in high-acid oil and gas fields.

-

Pharmaceutical and Food Industry: Process piping requiring high cleanliness and corrosion resistance.

-

Pulp and Paper Industry: Bleaching sections.

-

Wastewater Treatment: Especially wastewater treatment systems containing high concentrations of chlorides and oxidants.

-

Marine Engineering: Seawater cooling systems, subsea pipelines, and other high-Cl⁻ environments.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!