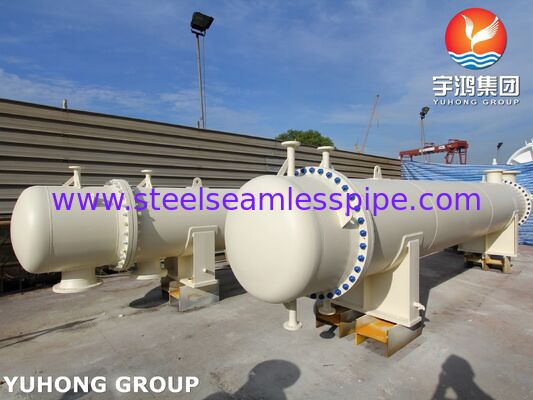

AES Type Floating Head Heat Exchanger | ASME U Stamped | TP316L Tubes for Severe Service & Easy Maintenance

Yuhong Holding Group: Engineering Heavy-Duty Process Equipment

Yuhong Holding Group Co., Ltd. designs and manufactures certified thermal and pressure systems for global industries. Our comprehensive capabilities cover ASME code shell & tube heat exchangers (including floating head, fixed tube sheet, and U-tube designs), pressure vessels, and air coolers. We are also a reliable source for precision replacement tube bundles, heat exchanger tubes, finned tubes, and all ancillary components.

Product Overview: The Maintainable & Robust AES Floating Head Exchanger

The AES Floating Head Heat Exchanger represents an optimal solution for demanding processes where thermal stress, frequent cleaning, or corrosive media are primary concerns. This ASME U Stamp certified unit is constructed with TP316L stainless steel tubing, offering a blend of superior corrosion resistance, mechanical integrity, and unparalleled serviceability for long-term operational efficiency.

Design Configuration & Key Components

| Major Assembly |

Standard Specification / Typical Material |

Function & Design Rationale |

| Tube Bundle (Removable) |

Tubes: ASME SB213 TP316L |

The core heat transfer element. TP316L provides enhanced pitting resistance. The entire bundle can be extracted for maintenance. |

| Floating Head Assembly |

Cover: SA182 F316L / Gasketed Joint |

Allows tubesheet and bundle to expand/contract independently of the shell, eliminating thermal stress. Key to the "stress-free" design. |

| Shell & Shell Cover |

ASME SA516 Gr. 70 or SA240 316L |

Contains the shell-side fluid. The rear cover is removable to access the floating head and pull the bundle. |

| Stationary Tubesheet & Channel |

SA182 F316L / SA516 Gr.70 |

Provides the fixed tube-side fluid inlet/outlet and allows easy inspection of tube ends without bundle removal. |

| Baffle System |

SA516 Gr.70 or SA240 316L |

Configurable (segmental, double segmental) to optimize shell-side flow velocity, heat transfer, and tube support. |

Technical Focus: Why Choose a Floating Head Design?

Addressing Thermal Expansion

When a large temperature difference (typically > 50°C) exists between the shell-side and tube-side fluids, the metal components expand differently. The floating head design absorbs this difference through its internal movable components, preventing destructive thermal stresses that fixed tubesheet heat exchangers cannot safely achieve.

Simplified Maintenance and Inspection

The tube bundle can be completely removed, fully exposing all tube surfaces and the shell interior, facilitating mechanical cleaning, non-destructive testing (NDT), or individual tube blockage/replacement. This is crucial for processes prone to scaling or requiring regular integrity verification.

Handling Temperature and Pressure Differences

This design is typically suitable for higher design pressure and temperature ranges, providing process engineers with greater operational flexibility.

Key Advantages and Customized Services

- ASME Compliance Assurance: From design review and material procurement to final inspection and stamping, the entire process adheres to the ASME Boiler and Pressure Vessel Code, ensuring compliance and safety documentation accepted for projects worldwide.

- Material and Process Compatibility: We can recommend the most economical material compatibility based on your specific process fluids (e.g., chloride-containing, acidic media), optimizing from tube bundles to shell.

- Extended Operating Cycle: The combination of easy-to-maintain design and corrosion-resistant materials significantly reduces unplanned downtime and lowers the total cost of ownership (TCO) over its entire lifecycle.

- Wide Range of Applications: Particularly suitable for the refining industry (e.g., crude oil heat exchange), chemical reaction systems, lubricating oil cooling, and any fouling-prone service requiring regular cleaning.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!