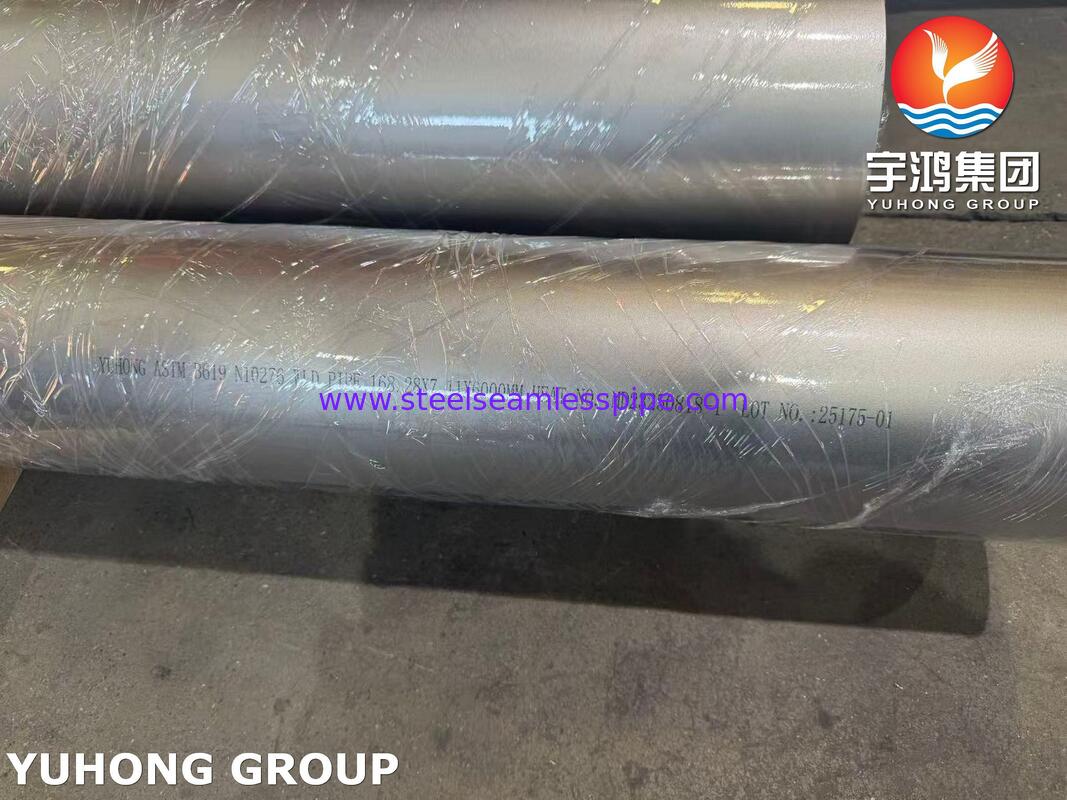

ASTM B619 N10276 Nickel Alloy Welded Pipe for High Temperature

ASTM B619 standard specifies the manufacturing requirements for nickel and nickel alloy welded pipes, covering processes, chemical composition, mechanical properties, dimensional tolerances, inspection and testing, etc. N10276 nickel-based alloy, commonly known as Hastelloy C-276, is a nickel-chromium-molybdenum solid solution strengthened nickel-based superalloy with added tungsten.

ASTM B619 N10276 Nickel Alloy Steel Chemical Composition

| UNS GRA. |

ASTM B619 N10276 CHEMICAL COMPOSITION % MAXIMUM |

| C |

MN |

P |

S |

SI |

CR |

NI |

MO |

FE |

W |

| N10276 |

0.01 |

1.0 |

0.04 |

0.03 |

0.08 |

14.5-16.5 |

REM |

15.0-17.0 |

4.0-7.0 |

3.5-4.0 |

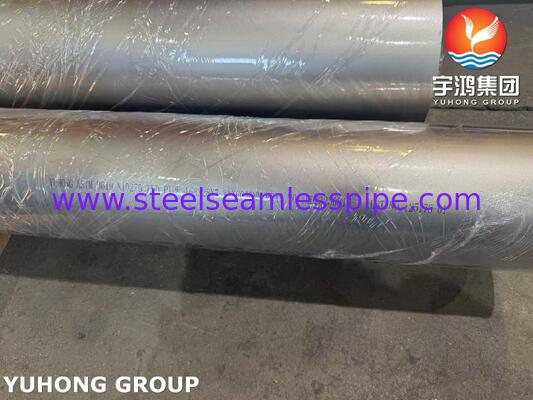

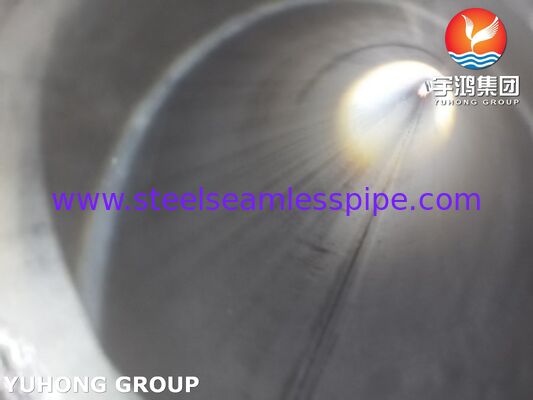

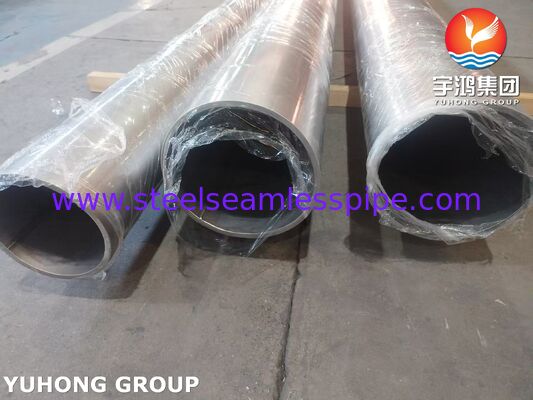

Manufacturing process: Welded pipes are typically manufactured using precision welding methods such as automated tungsten inert gas welding (TIG) or plasma arc welding, by rolling and welding alloy strips or plates.

Features: Compared to seamless pipes, welded pipes offer greater economic efficiency and dimensional flexibility for large diameters and thin-walled specifications.

ASTM B619 N10276 Nickel Alloy Welded Pipe Core Advantages

1.Excellent corrosion resistance: Performs well in both oxidizing and reducing media, resisting pitting corrosion, crevice corrosion, and stress corrosion cracking.

2.Broad corrosion resistance range: Exhibits excellent resistance to various acids such as sulfuric acid, hydrochloric acid, and phosphoric acid, chloride ions, wet chlorine gas, and hypochlorites.

3.Good thermal stability: Maintains performance at high temperatures, suitable for high-temperature corrosive environments.

Excellent weldability: An alloy specifically designed for weldability, minimizing the formation of harmful precipitates after welding.

ASTM B619 N10276 Nickel Alloy Steel Mechanical Property Requirements

|

UNS GRA.

|

Tensile Strength,

min, ksi [MPa]

|

Yield Strength,

0.2 % Offset, min,

ksi (MPa)

|

Elongation in

2 in. or 50 mm or 4D,

min, %

|

| N10276 |

100[690] |

41[283]

|

40

|

ASTM B564 N10276 Nickel Alloy Steel Flange Required Nondestructive Testing

When specified by the purchaser, each lot shall be inspected piece by piece. The purchaser shall specify whether one or both tests are required:

- Ultrasonic Testing: This shall be conducted in accordance with MIL-STD-271 (as modified from ASME SB564).

- Liquid Penetrant Testing: This shall be conducted in accordance with MIL-STD-271.

ASTM B619 N10276 Nickel Alloy Welded Pipe Main Application

- Chemical and Petrochemical Industries

- Flue Gas Desulfurization Systems

- Pulp and Paper Industry

- Waste and Wastewater Treatment

- Nuclear Fuel Reprocessing

- Marine Engineering and Seawater Applications

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!