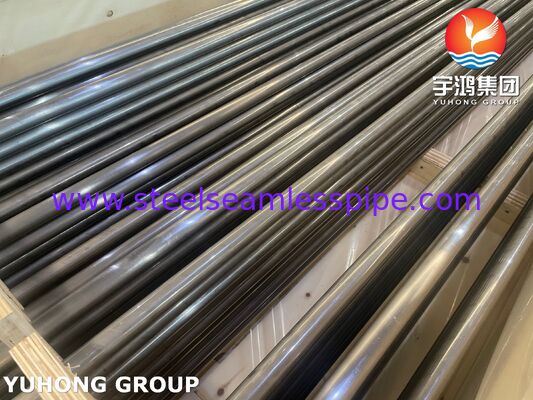

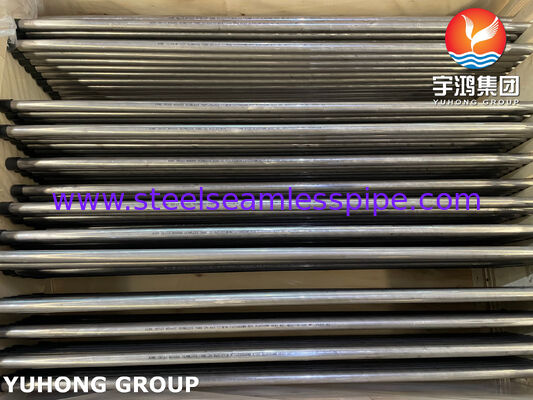

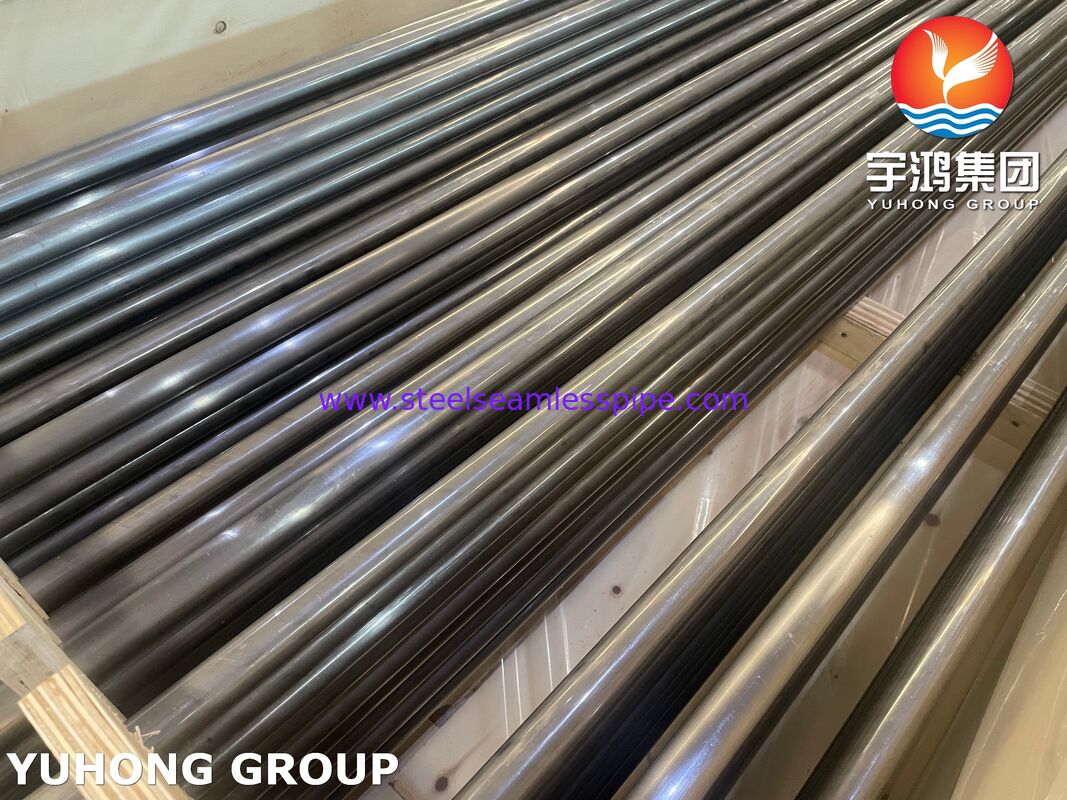

Heat Exchanger Tube ASME SB163 Nickel Alloy N04400 Monel Alloy 400 Seamless U Bend Tube

ASME SB163 specifies the material specifications for seamless nickel and nickel alloy condenser and heat exchanger tubes:

N04400 (UNS N04400) is Monel Alloy 400.

Its basic composition is 67% nickel and 30% copper, with trace amounts of iron, manganese, and other elements.

It exhibits excellent corrosion resistance. It performs well in many environments, especially in seawater, brine, sulfuric acid, hydrofluoric acid, and alkaline solutions.

It maintains good mechanical properties over a wide temperature range from low temperatures to approximately 1000°F (540°C).

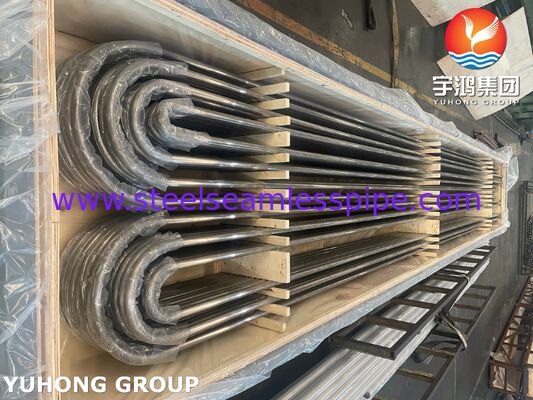

U Bend Tube Noted:

The U-shaped tubes made from this material are effective in shell-and-tube heat exchangers operating in harsh environments with large temperature differences.

During the design process, the radius (R) of the bend needs to be confirmed with the customer. An excessively small radius will lead to excessive thinning of the outer bend wall, wrinkling of the inner bend wall, and the generation of significant residual stress.

The spacing between the two straight tubes in the U-bend section is also important.

Ensure that the tubes can smoothly pass through the baffle orifice, and allow sufficient space for thermal expansion.

| Chemical Composition (Weight % - Wt.%) |

| Element |

Minimum (%) |

Maximum (%) |

Key Role / Effect |

| Nickel (Ni) |

63 |

(Balance) |

Base element; provides fundamental corrosion resistance & ductility. |

| Copper (Cu) |

28 |

34 |

Enhances resistance to sulfuric & hydrofluoric acids, and seawater. |

| Iron (Fe) |

- |

2.5 |

Impurity control; improves strength in specific environments. |

| Manganese (Mn) |

- |

2 |

Deoxidizer during melting; improves forgeability. |

| Carbon (C) |

- |

0.3 |

Impurity control; impacts intergranular corrosion in heated zones. |

| Silicon (Si) |

- |

0.5 |

Improves melt fluidity and oxidation resistance. |

| Sulfur (S) |

- |

0.024 |

Harmful impurity; severely restricted to prevent hot brittleness. |

| Other Elements |

- |

0.5 (Total) |

Includes incidental/impurity elements. |

| Mechanical Properties |

| Property |

Requirement (Minimum) |

Typical Value Range |

| Tensile Strength |

70 ksi (480 MPa) |

75-85 ksi (515-585 MPa) |

| Yield Strength (0.2% Offset) |

25 ksi (170 MPa) |

28-35 ksi (195-240 MPa) |

| Elongation (in 2 inches or 50mm) |

35% |

40-50% |

| Hardness (Rockwell) |

Not Specified |

Typically B65 - B85 |

| Hydrostatic Test Pressure |

Required per formula |

- |

Application:

Seawater cooling pipework & systems

Shipboard heat exchangers & condensers

Desalination plant evaporator & heater tubes

Offshore platform piping systems

Chemical & Petrochemical Processing

Heat exchangers & reactors handling sulfuric and hydrofluoric acid (HF)

Oil & Gas Production & Refining

Heat exchangers in sour gas

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!