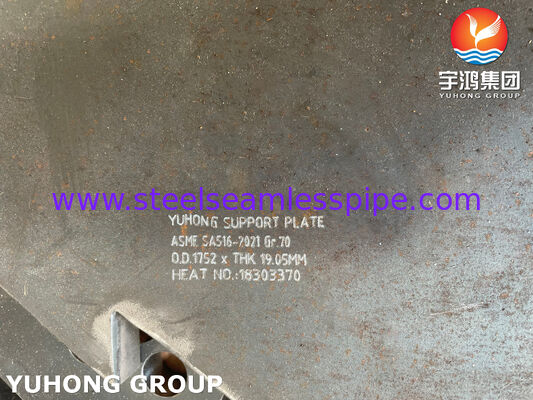

Carbon Steel Baffle Plate Support Plate ASME SA516 GR.70 For Heat Exchanger

Product Overview

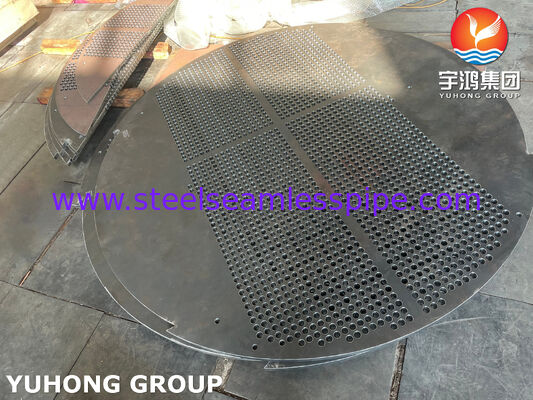

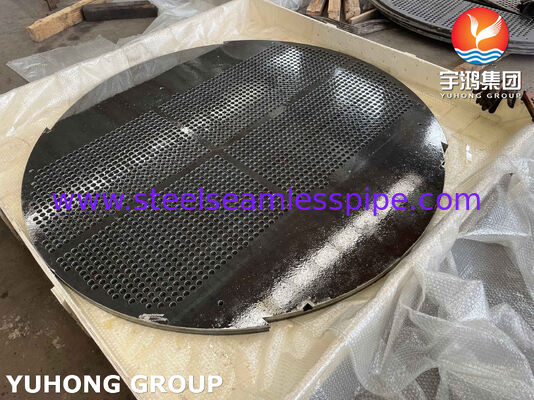

Our Baffle and Support Plates are fabricated from ASME SA516 Grade 70 Carbon Steel, the industry-preferred material for internal components in shell-and-tube heat exchangers and pressure vessels. These plates play a critical, dual role: Baffle Plates direct shell-side fluid flow across the tube bundle for optimal heat transfer efficiency, while Support Plates prevent tube sagging and vibration-induced damage. Manufactured to precise TEMA standards, they ensure reliable performance and longevity in demanding industrial services.

Key Features & Advantages

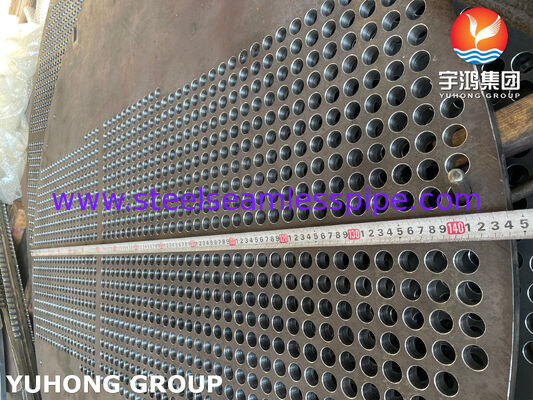

Dual-Function Design: Baffle Plates (with segmental, double-segmental, or disc-and-doughnut cuts) create turbulent flow and increase heat transfer coefficients. Support Plates (with larger clearance holes) provide essential mid-span support for long tube bundles, safeguarding against failure.

Optimal Balance of Strength & Economy: SA516 Gr.70 provides excellent strength and toughness at a competitive cost, making it the standard choice for most water, steam, oil, gas, and non-aggressive chemical services.

Superior Fabricability & Consistency: This normalized steel plate offers consistent machining properties, allowing us to produce clean, precise cut edges and tube holes with tight tolerances for a perfect fit within the exchanger shell.

Proven Reliability: As a pressure vessel quality plate, SA516 Gr.70 is known for its dependable performance under thermal cycling and mechanical stress, contributing to the overall structural integrity of the heat exchanger.

Material Traceability: All plates can be supplied with complete Material Test Reports (MTRs) certifying compliance with ASME SA516 Gr.70 specifications for chemistry and mechanical properties.

Primary Functions in a Heat Exchanger:

Baffle Plate: Directs shell-side fluid, increases velocity, improves heat transfer, and reduces dead zones.

Support Plate: Provides mechanical support to tubes, minimizes deflection, and dampens flow-induced vibration (FIV).

Typical Applications

Power Generation: Feedwater heaters, condensers, lube oil coolers.

Oil & Gas Refining: Crude oil exchangers, product coolers.

Chemical & Petrochemical: Various process heaters and coolers.

HVAC & General Industry: Shell-and-tube heat exchangers for multiple cooling/heating duties.

Technical Specifications (Summary)

Material Standard: ASME SA516 / ASTM A516, Grade 70 (Normalized).

Plate Thickness: Custom manufactured per client drawings (common range: 3/16” to 1”+).

Design & Cutting: Precision-cut to specified baffle type (segmental cut %, etc.) and tube hole layout per TEMA standards and client specifications.

Key Certification: Material Test Certificate (MTR) available upon request.

Why Choose Our Baffle & Support Plates?

We understand that internal components are vital to exchanger performance and durability. By using certified materials and precision cutting, we ensure our plates contribute to efficient heat transfer and reliable, vibration-free operation of your entire tube bundle.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!