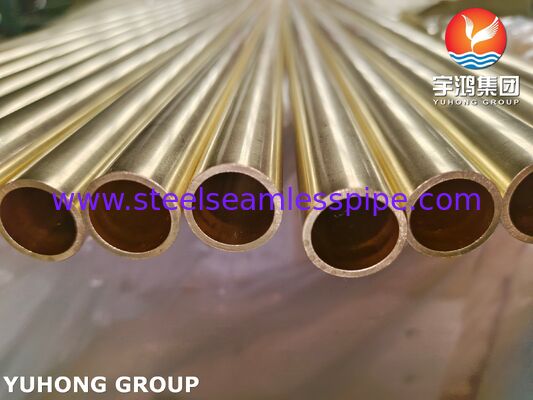

ASTM B111 / ASME B111 C44300 O61 Copper Nickel Alloy Tube

ASTM/ASME B111 C44300 O61 tubing is an annealed, arsenic- and tin-fortified seamless copper-nickel alloy tube.

It is specifically designed to address dezincification corrosion in seawater environments, providing excellent resistance to seawater corrosion and marine organism adhesion while maintaining good thermal conductivity and processability.

It is a reliable choice for condenser and heat exchanger piping in ships, coastal power plants, and desalination plants.

Comparison with other copper-nickel alloys:

C44300 vs. C70600: C44300 contains Zn and Sn, offering stronger corrosion resistance (especially against dezincification) and slightly higher strength, but it is generally more expensive.

C44300 vs. C71500: The standard 70/30 copper-nickel alloy (C71500) contains little or no Zn/Sn, providing higher resistance to seawater flow corrosion and stress corrosion cracking. It is a "purer" copper-nickel alloy, typically used in harsher high-flow-rate environments. C44300 can be seen as a more cost-effective option specifically optimized for dezincification corrosion.

C44300 vs. C68700: C44300 generally outperforms aluminum brass in strength and corrosion resistance, particularly in its resistance to erosion corrosion.

| Chemical Composition |

| Element |

Composition Range (%) |

Typical / Notes |

| Copper |

70.0 - 73.0 |

Remainder |

| Tin |

0.9 - 1.2 |

Key for strength and corrosion resistance. |

| Zinc |

Rem. (Remainder) |

Principal alloying element. |

| Iron |

≤ 0.06 |

Maximum. |

| Lead |

≤ 0.07 |

Maximum. |

| Arsenic |

0.02 - 0.10 |

Essential - Impedes dezincification corrosion. |

| Other Elements (total) |

≤ 0.15 |

Maximum. |

| Mechanical Properties |

| Temper Designation |

Condition |

Tensile Strength, min |

Yield Strength (0.5% Ext. Under Load), min |

Elongation in 2 in (50 mm), min |

|

|

| O61 (Annealed) |

Soft |

ksi |

MPa |

ksi |

MPa |

% |

| 40 |

275 |

15 |

105 |

40 |

| H55 |

Hard Drawn |

ksi |

MPa |

ksi |

MPa |

% |

| 52 |

360 |

40 |

275 |

20 |

Application:

Marine Seawater Cooling Systems

Marine condensers, lubricating oil coolers, intercoolers

Submarine pipeline systems

Main condenser tubes for coastal or river power plants

Auxiliary cooling systems

Seawater desalination plants

Coolers using seawater as the cooling medium

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!