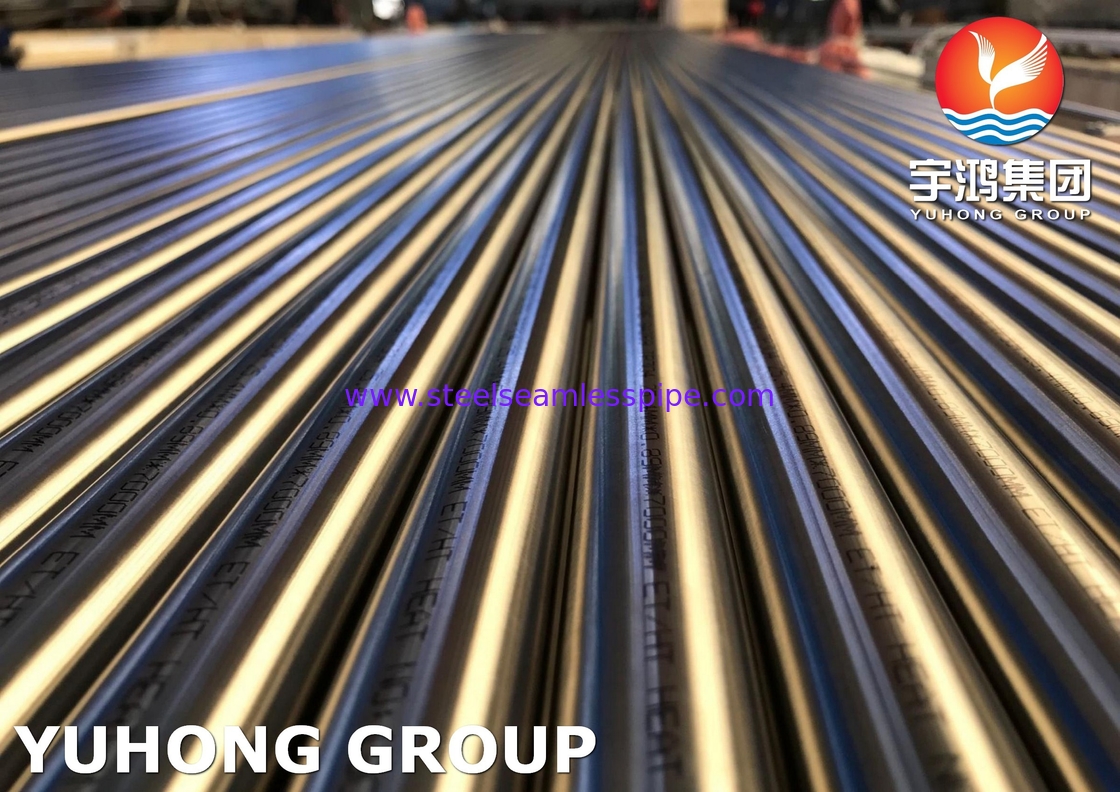

ASTM A269/ASME SA269 TP304/304L STAINLESS STEEL TUBE BRIGHT ANNEALED

Overview

Type 304 Stainless Steel has excellent welding and deep drawing characteristics - it is easy to fabricate, easy to clean and aesthetically pleasing to the eye.

Type 304L is a lower carbon variant of Grade 304 - the steel can be welded without the resulting issue of carbon precipitation (precipitation of chromium carbide as heat is applied during the welding process which depletes the chromium element of the steel thus reducing its anti-corrosive/oxidation effectiveness). As a result, Type 304L stainless steel is a sort after material for use in severely corrosive conditions. Weld annealing is only necessary in applications where stress loads are excessive.

Grade 304 can also be found in heat exchangers, chemical containers, pipelines and throughout the brewing industry. It can be used as a fabricated material where high temperature petroleum gases or steam production gases are stored such as pressure vessels. It can even be found extensively in the construction industry where the material is used for cosmetic purposes such as building fascias.

304 & 304L plate and pipe have similar properties and in certain cases are stocked with Dual Certification, where it is concluded that each item has properties and a composition which comply with both steel types. Grade 304H cannot be included in this equation due to the steel's higher carbon content which is intended for use in elevated temperature applications. ASTM A269 TP 304 / 304L Stainless Steel Seamless Pipes and Tubes Composition.

Bright annealed tube under a reducing atmosphere or in a vacuum protection, after high temperature solid melting and rapid cooling to get the stainless steel tube, requiring the inner surface has a very good surface roughness and cleanliness, is a comprehensive consideration of organizational stability corrosion resistance and workability of the pipe.

Bright annealed tube inner surface roughness Ra values and their own cleanliness is extremely demanding, so the particles can occur during transport and accumulation of fluid retention has been effectively curbed. In addition, the chemical composition of the pipe and the base material dimensional tolerances need to be strictly controlled to ensure the weldability of steel and the welding quality in the welding fumes, which can reduce the occurrence of particle generation and improving the corrosion resistance of welded parts, and smoothness.

ASTM A269 TP304 Stainless Steel Seamless Tubes range

|

ASTM A269 TP304 Stainless Steel Tubes Specification

|

ASTM A-249, A-268, A-269, A-270, A-554, A-688, A-778, DIN 17455, DIN 17456, 17457, DIN 17458 [Class 1] & Its equivalent ASME, DIN & EN Standard.

|

|

ASTM A269 TP304 Stainless Steel Tubes Grades

|

202, 304, 304L, 304H, 304LN, 309S, 310S, 316, 316L, 316H, 316Ti, 316LN, 317L, 321, 321H, 347, 347H, 904L, SMO 254, ALLOY 254, 6MO, 6MOLY, UNS S31254 ETC.

|

|

ASTM A269 TP304 Stainless Steel Tubes Type

|

Seamless / Welded / ERW / EFW / Cold Draw / Hot Finish / Cold Finish

|

|

ASTM A269 TP304 Stainless Steel Tubes Outer Diameter Size

|

Seamless - 6 MM OD TO 114.3 MM OD

Welded / ERW- 10 MM TO 114.3 MM OD

|

|

ASTM A269 TP304 Stainless Steel Tubes Wall Thickness

|

0.8 MM TO 4 MM Wall Thickness

|

|

ASTM A269 TP304 Stainless Steel Tubes Length

|

01 Meter to 12.5 Meters, Single Random Length, Double Random Length And Customize Size.

|

|

ASTM A269 TP304 Stainless Steel Tubes Ends

|

Plain Ends / Beveled Ends

|

|

ASTM A269 TP304 Stainless Steel Tubes Delivery Conditions

|

As Rolled, Formed, Stress Relieved, Annealed, Hardened, Tempered, Cold Draw

|

|

ASTM A269 TP304 Stainless Steel Tubes Coating

|

Electropolish, Mechanical Polish, Satin Finish, Passivated

|

|

ASTM A269 TP304 Stainless Steel Tubes Other Testing

|

Product Analysis, Transverse Tension Test, Flattening Test, Etching Test, Radiograph HIC Examination, Stabilizing Heat Treatment, Intergranular Corrosion Test, Weld Decay Test, Magnetic Particle Detection, Grain Size Test, NACE 0175, Dual Grade, PWHT (POST WELD HEAT TREATMENT), Flare Test, Bend Test, Hardness Test, Tensile Test etc

|

|

ASTM A269 TP304 Stainless Steel Tubes Dimension

|

All Pipes Is Manufactured and Inspected / Tested to the Relevant standards including ASTM And ASME

|

|

ASTM A269 TP304 Stainless Steel Tubes Value Added Services

|

Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat Treatment / Annealed / Bright Annealed

|

|

ASTM A269 TP304 Stainless Steel Tubes Packaging

|

Loose / Bundle / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector

|

|

ASTM A269 TP304 Stainless Steel Tubes Shipment & Transportation

|

By Road - Truck / Train, By Sea - Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air - Freighter Civil Passenger and Cargo Planes

|

|

ASTM A269 TP304 Stainless Steel Tubes Material Test Certificate

|

Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC

|

Chemical Composition of ASTM A269 TP304 Stainless Steel Seamless Tubes

The chemical composition of grade 304 Stainless Steel is outlined in the following table

|

Grade

|

C

|

Mn

|

Si

|

P

|

S

|

Cr

|

Mo

|

Ni

|

N

|

|

304

|

min.

|

-

|

-

|

-

|

-

|

-

|

18.0

|

-

|

8.0

|

-

|

|

max.

|

0.08

|

2.0

|

0.75

|

0.045

|

0.030

|

20.0

|

|

10.5

|

0.10

|

|

304L

|

min.

|

-

|

-

|

-

|

-

|

-

|

18.0

|

-

|

8.0

|

-

|

|

max.

|

0.030

|

2.0

|

0.75

|

0.045

|

0.030

|

20.0

|

|

12.0

|

0.10

|

|

304H

|

min.

|

0.04

|

-

|

-

|

-0.045

|

-

|

18.0

|

-

|

8.0

|

-

|

|

max.

|

0.10

|

2.0

|

0.75

|

|

0.030

|

20.0

|

|

10.5

|

|

Mechanical Properties of ASTM A269 TP304 Stainless Steel Seamless Tubes

The Mechanical Properties of grade 304 Stainless Steel are displayed in the following table.

|

Grade

|

Tensile Strength (MPa) min

|

Yield Strength 0.2% Proof (MPa) min

|

Elongation (% in 50mm) min

|

Hardness

|

|

Rockwell B (HR B) max

|

Brinell (HB) max

|

|

304

|

515

|

205

|

40

|

92

|

201

|

|

304L

|

485

|

170

|

40

|

92

|

201

|

|

304H

|

515

|

205

|

40

|

92

|

201

|

|

304H also has a requirement for a grain size of ASTM No 7 or coarser.

|

ASTM A269 TP304 Stainless Steel Seamless Tubes Physical Properties

Physical properties of 304 grade stainless steel in the annealed condition

|

Grade

|

Density (kg/m3)

|

Elastic Modulus (GPa)

|

Mean Coefficient of Thermal Expansion (μm/m/°C)

|

Thermal Conductivity (W/m.K)

|

Specific Heat 0-100°C (J/kg.K)

|

Electrical Resistivity (nΩ.m)

|

|

0-100°C

|

0-315°C

|

0-538°C

|

at 100°C

|

at 500°C

|

|

304/L/H

|

8000

|

193

|

17.2

|

17.8

|

18.4

|

16.2

|

21.5

|

500

|

720

|

Specification Comparison For Grade ASTM A269 TP304 Stainless Steel Seamless Tubes

Grade specifications for 304 grade stainless steel

|

Grade

|

UNS No

|

Old British

|

Euronorm

|

Swedish SS

|

Japanese JIS

|

|

BS

|

En

|

No

|

Name

|

|

304

|

S30400

|

304S31

|

58E

|

1.4301

|

X5CrNi18-10

|

2332

|

SUS 304

|

|

304L

|

S30403

|

304S11

|

-

|

1.4306

|

X2CrNi19-11

|

2352

|

SUS 304L

|

|

304H

|

S30409

|

304S51

|

-

|

1.4948

|

X6CrNi18-11

|

-

|

-

|

|

These comparisons are approximate only. The list is intended as a comparison of functionally similar materials not as a schedule of contractual equivalents. If exact equivalents are needed original specifications must be consulted.

|

ASTM A269 TP304 Stainless Steel Seamless Tubes Applications

The grade 304 steel can be made into plates, sheets, and coils to be used in the following:

-

Food processing equipment, particularly in beer brewing, milk processing & wine making.

-

Kitchen benches, sinks, troughs, equipment and appliances

-

Architectural panelling, railings & trim

-

Chemical containers, including for transport

-

Heat Exchangers

-

Woven or welded screens for mining, quarrying & water filtration

-

Threaded fasteners

-

Springs

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!