Duplex Stainless Steel Pipes, ASTM A789, ASTM A790, S31803, S32750, S32205, S31254MO.

YUHONG SPECIAL STEEL deal with Austenitic Stainless Steel, Nickel Alloy Steel(Hastelloy , Monel, Inconel, Incoloy ) seamless and welded pipe and tube already more than 25 years, every year sell more than 80000 tons of steel pipe and tube. Our client already cover more than 45 countries, Like Italy, UK, Gernmany, USA, Canada, Chile, Colombia, Saudi Arabia, Korea, Singapore, Austrial, Poland, France , ....And our group branch company and factory have been already approved by :ABS, DNV, GL, BV, PED 97/23/EC, AD2000-WO, GOST9941-81, CCS, TS, CNNC, ISO9001-2008, ISO 14001-2004.

Duplex Stainless Steel

UNS S31803 - UNS S32205

Duplex Plate/Sheet

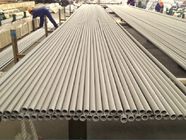

Duplex Seamless & Welded Tube

Duplex Seamless & Welded Pipe

Duplex Round Bar

Duplex Flanges F51

Duplex Specialty Forgings

Duplex Seamless & Welded BW Fittings

|

Trade Name

|

UNS

|

Duplex Stainless Steel Industry Specifications

|

Chemical

Composition

|

Min.Tensile

(KSI)

|

Min.Yield

(KSI)

|

Elongation

%

|

|

2205®

22Cr

|

UNS S31803

|

ASME SA-182 (F51), SA-240, SA-798, SA-790, SA-815

ASTM A182 (F51),A240, A276, A479, A789, A790, A815, A928, A988

SAE J405

|

C 0.30 max

Cr 21.0-23.0

Mn 2.00 max

Mo 2.50-3.50

N 0.08-0.20

Ni 4.50-6.50

P 0.030 max

S 0.020 max

Si 1.00 max

|

90

|

65

|

25

|

|

2205®

22Cr

|

UNS S32205

|

ASME SA-182 (F60), SA-240, SA-798, SA-790, SA-815

ASTM A182 (F60), A240, A276, A479, A480, A798, A790, A815, A928, A988

SAE J405

|

C 0.30 max

Cr 22.0-23.0

Mn 2.00 max

Mo 3.00-3.50

N 0.14-0.20

Ni 4.50-6.50

P 0.030 max

S 0.020 max

Si 1.00 max

|

95

|

65

|

25

|

2205® is a registered trademark for Sandvik

General Duplex stainless steel information

2205 is the most widely used duplex (ferritic/austenitic) stainless steel grade. It finds applications due to both excellent corrosion resistance and high strength. The standard duplex S31803 composition has over the years been refined by many steel suppliers, and the resulting restricted composition range was endorsed as UNS S32205 in 1996. Duplex S32205 gives better guaranteed corrosion resistance, but for much of the Duplex S31803 currently produced also complies with Duplex S32205. 2205 is not generally suitable for use at temperatures above 300ºC as it suffers from precipitation of brittle micro-constituents, nor below -50ºC because of its ductile-to-brittle-transition.

Duplex Applications

Chemical processing, transport and storage,

Oil and Gas exploration and processing equipment,

Marine and other high chloride environments,

Pulp and paper digesters, liquor tanks and paper machines.

Duplex Corrosion Resistance

Excellent general corrosion resistance; superior to Grade 316 in most environments. Excellent resistance to localized corrosion including intergranular, pitting and crevice corrosion; the CPT of 2205 is generally at least 35ºC. The grade is also resistant to chloride stress corrosion cracking (SCC) at temperatures of up to about 150ºC. Grade 2205 will often perform well in environments which cause premature failure of austenitic grades. It has better resistance to sea water then Grade 316.

Duplex Heat Resistance

Although 2205 has good high temperature oxidation resistance, this grade - like other duplex stainless steels - suffers from embrittlement if held for even short times at temperatures above 300ºC. If embrittled, this can only be rectified by a full solution annealing treatment. Duplex stainless steels are almost never used above 300ºC.

Duplex Heat Treatment

Solution treatment (annealing) - heat to 1020ºC-1100ºC and cool rapidly. This grade cannot be hardened by thermal treatment, but does work harden.

Classification Society Criterion:CSS,DNV,GL,LR,NK,KR,ABS,BV

Some of the quality tests carried out by us includes:

|

Corrosion Test

|

Conducted only when specially requested by the client

|

|

Chemical Analysis

|

Test done as per required quality standards

|

|

Destructive / Mechanical Testing

|

Tensile | Hardness | Flattening | Flare | Flange

|

|

Reverse-bend and Re. flat tests

|

Carried out in full compliance with relevant standards & ASTM A-450 and A-530 norms, which ensures trouble-free expansion, welding & use at customers end

|

|

Eddy Current Testing

|

Done to detect homogeneities in subsurface by using Digital Flaw-mark Testing System

|

|

Hydrostatic Testing

|

100% Hydrostatic Testing carried out according to ASTM-A 450 norms for checking tube leakage, and biggest pressure we can support 20Mpa/7s .

|

|

Air Under Pressure Test

|

To check any evidence of air leakage.

|

|

Visual Inspection

|

After passivation, every single length of tubes & pipes is subjected to thorough visual inspection by trained staff for detecting surface flaws & other imperfections

|

Supplementary Testing : Apart from the above mentioned tests, we also carry out on the manufactured products supplementary testing. The tests conducted under this include:

-

Eddy Current Testing

-

O.P Testing

-

Radiography Testing

|

-

Corrosion Testing

-

Micro Testing

-

Macro Testing

|

-

IGC Testing

-

Ultrasonic testing

-

Liquid Penetrate testing

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!