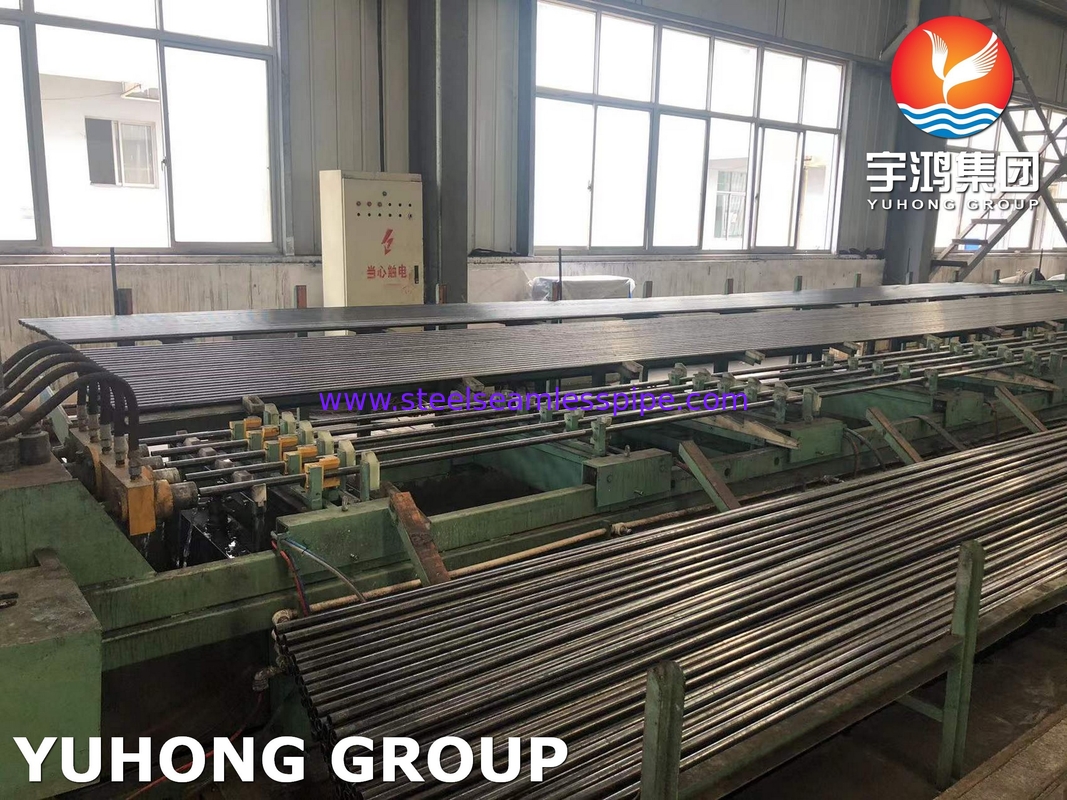

ASTM A179 ASME SA179 Seamless Carbon Steel Boiler Tubing / tube / tubes, Gr. A , GR.C,25.4MM

Application: For high, middle, low pressure boiler and pressure purpose

Production Standard, Grade, Steel No:

ASTM A178 Grade A, C, D

ASTM A179 Grade A, C, D

ASTM A192

ASTM A210 GradeA-1, C

BS3059-Ⅰ 320 CFS

BS3059-Ⅱ 360, 440, 243, 620-460, 622-490, S1, S2, TC1, TC2

EN10216-1 P195TR1/TR2, P235TR1/TR2, P265TR1/TR2

EN10216-2 P195GH, P235GH, P265GH, TC1, TC2

DIN17175 ST35.8, ST45.8

DIN1629 ST37.0, ST44.0, ST50.0

JIS G3454 STPG370, STPG410

JIS G3461 STB340, STB410, STB440

GB5310 20G, 15MoG, 12CrMoG, 12Cr2MoG, 15CrMoG, 12Cr1MoVG, 12Cr2MoWVTiB

GB9948 10, 20, 12CrMo, 15CMo

GB3087 10, 20

Delivery Condition:Annealed, Normalized, Normalized and Tempered

Inspection and Test:

Chemical Composition Inspection, Mechanical Properties Test(Tensile Strength,Yield Strength,

Elongation, Flaring, Flattening, Bending, Hardness, Impact Test), Surface and Dimension Test,No-destructive Test, Hydrostatic Test.

Surface treatment:

Oil-dip, Varnish, Passivation, Phosphating, Shot Blasting

| Tube Sizes for Heat Exchangers & Condensers & Boiler |

| Outside Diameter |

|

BWG |

| 25 |

22 |

20 |

18 |

16 |

14 |

12 |

10 |

| |

Wall Thickness mm |

| 0.508 |

0.71 |

0.89 |

1.24 |

1.65 |

2.11 |

2.77 |

3.40 |

| mm |

inch |

|

Weight kg/m |

| 6.35 |

1/4 |

0.081 |

0.109 |

0.133 |

0.174 |

0.212 |

|

|

|

| 9.53 |

3/8 |

0.126 |

0.157 |

0.193 |

0.257 |

0.356 |

0.429 |

|

|

| 12.7 |

1/2 |

|

0.214 |

0.263 |

0.356 |

0.457 |

0.612 |

0.754 |

|

| 15.88 |

5/8 |

|

0.271 |

0.334 |

0.455 |

0.588 |

0.796 |

0.995 |

|

| 19.05 |

3/4 |

|

0.327 |

0.405 |

0.553 |

0.729 |

0.895 |

1.236 |

|

| 25.4 |

1 |

|

0.44 |

0.546 |

0.75 |

0.981 |

1.234 |

1.574 |

2.05 |

| 31.75 |

1 1/4 |

|

0.554 |

0.688 |

0.947 |

1.244 |

1.574 |

2.014 |

2.641 |

| 38.1 |

1 1/2 |

|

0.667 |

0.832 |

1.144 |

1.514 |

1.904 |

2.454 |

3.233 |

| 44.5 |

1 3/4 |

|

|

|

1.342 |

1.774 |

2.244 |

2.894 |

3.5 |

| 50.8 |

2 |

|

|

|

1.549 |

2.034 |

2.574 |

3.334 |

4.03 |

| 63.5 |

2 1/2 |

|

|

|

1.949 |

2.554 |

3.244 |

4.214 |

5.13 |

| 76.2 |

3 |

|

|

|

2.345 |

3.084 |

3.914 |

5.094 |

6.19 |

| 88.9 |

3 1/2 |

|

|

|

2.729 |

3.609 |

4.584 |

5.974 |

7.27 |

| 101.6 |

4 |

|

|

|

|

4.134 |

5.254 |

6.854 |

8.35 |

| 114.3 |

4 1/2 |

|

|

|

|

4.654 |

5.924 |

7.734 |

9.43 |

| Form of Tube: Straight & U-bend & Finned & Coiled |

| Stainless Steel Tube: A/SA213, A/SA249, A/SA268, A/SA269, A/SA789, EN10216-5, A/SA688, B/SB163, JIS-G3463, GOST9941-81. |

|

Carbon &Alloy Steel Tube: A/SA178, A/SA179, A/SA192,A/SA209, A/SA210, A/SA213, A.SA214

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!