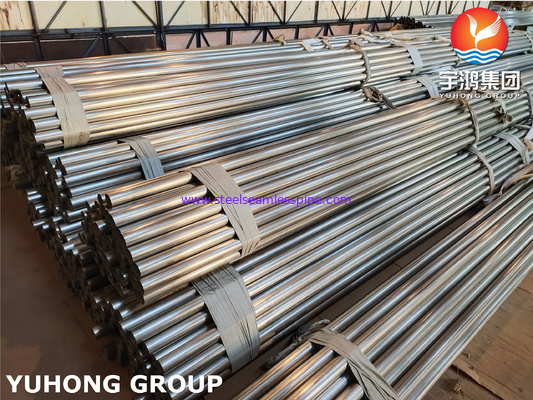

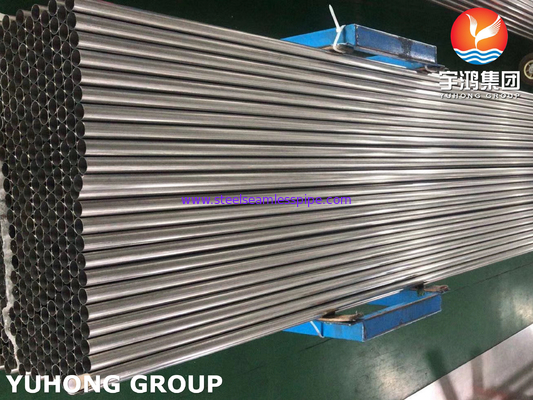

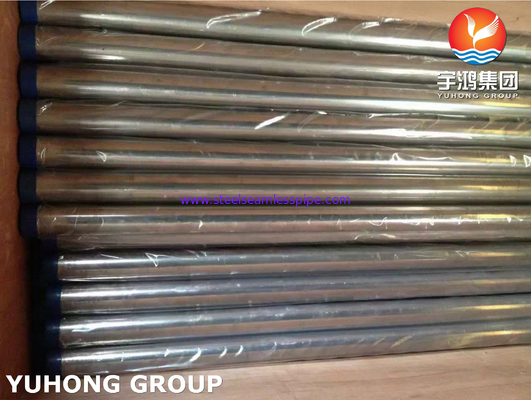

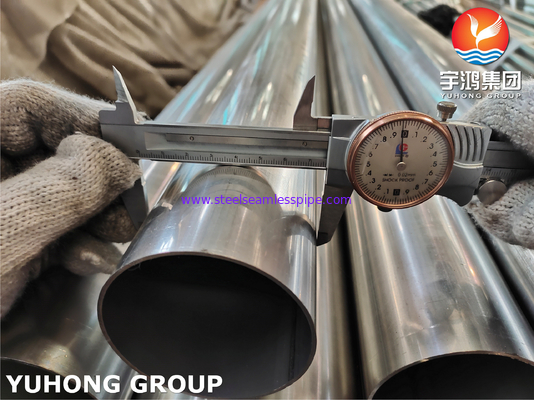

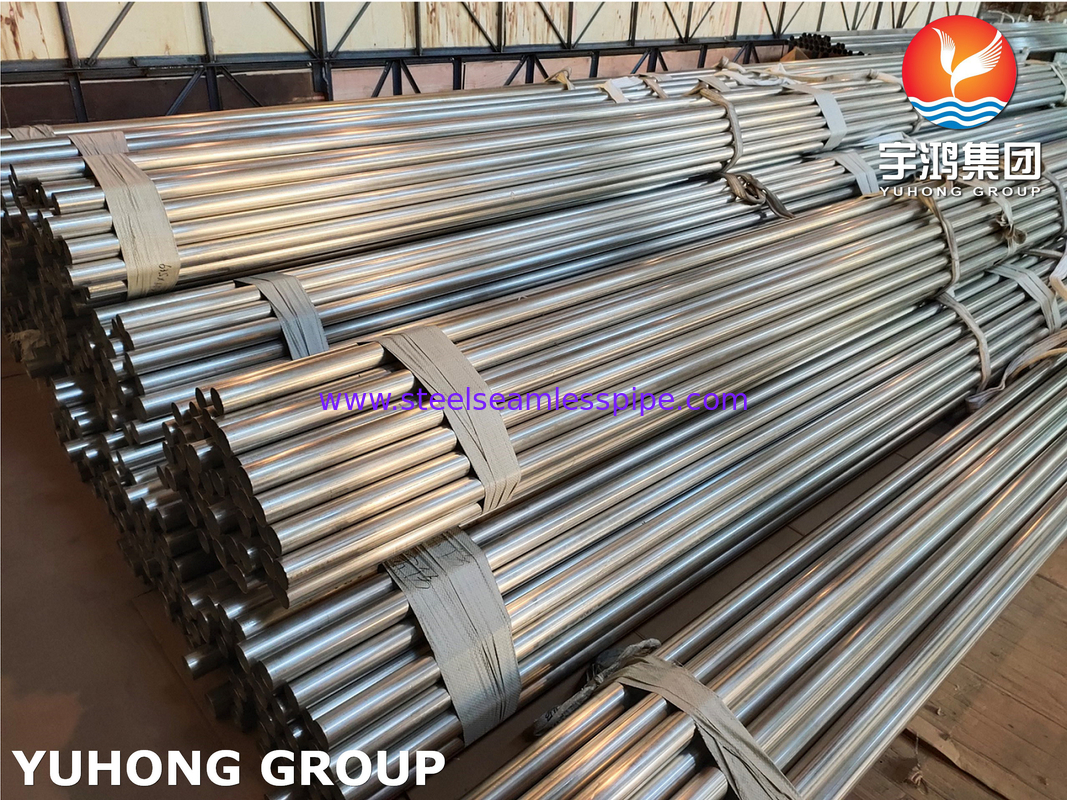

ASTM A249 / ASME SA249 TP316L BA Stainless Steel Welded Tube Heat Exchanger Tube

ASTM A249 is a standard specification for welded austenitic steel boiler, superheater, heat-exchanger, and condenser tubes. A249 stainless steel tubes are typically produced using either the electric-resistance-welding (ERW) or the automatic-welding (AW) process. The bright annealing process is used to produce a bright, reflective finish on the surface of the tube. Bright annealed stainless steel welded pipe is widely used in making military products, semiconductor, biological medicine, precision instruments and meters, hydraulic parts and many other industrial products.

ASTM/ASME SA249 TP316L Stainless Steel Welded Tube Equivalent Grade

| JIS |

WNR. / DIN |

UNS |

AISI |

EN |

GB |

| SUS316L |

1.4404 |

S31603 |

316L |

02Cr17Ni12Mo2 |

022Cr17Ni12Mo2 |

ASTM/ASME SA249 TP316L Stainless Steel Welded Tube Mechanical Properties

| |

Tensile Stress (Mpa) |

Yield Stress (Mpa) |

Elongation (%) |

Elongation (%) |

| SA 249 316L |

485 |

170 |

35 |

25 |

| 1.4404 |

490-690 |

190 |

40 |

30 |

ASTM/ASME SA249 TP316L Stainless Steel Welded Tube Chemical Composition

| SA 249 |

C |

Mn |

P |

S |

Si |

Ni |

Cr |

Mo |

N |

| 316L |

0.035 |

2.00 |

0.045 |

0.030 |

1.0 |

10-14 |

16-18 |

2-3 |

|

| 1.4404 |

0.03 |

2.00 |

0.040 |

0.015 |

1.0 |

10-13 |

16.5-18.5 |

2-2.5 |

0.11 |

Other Stainless Steel Welded Tube Material Grades

| American Standard |

TP304 , TP304L , TP310S , TP316 , TP316L , TP316Ti , TP321 , TP347 , 904L , S31803 Etc |

| European Standard |

1.4301 , 1.4306 , 1.4845 , 1.4401 , 1.4404 , 1.4571 , 1.4541 , 1.4550 , 1.4539 , 1.4462 Etc |

| German Standard |

X5CrNi18-10 , X2CrNi19-11 , X12CrNi25-21 , X5CrNi17-12-2 , X5CrNi17-12-3 , X2CrNiMo18-14-3 , X6CrNiTi18-10 , X6CrNiTb18-10 Etc |

Purpose and advantages of bright annealing:

1) Eliminate work hardening and obtain satisfactory metallographic structure.

2) Obtain a bright, non-oxidizing and corrosion-resistant surface.

3) Bright treatment keeps the rolling surface smooth, and a bright surface can be obtained without post-treatment.

Yuhong can provide various material grades, including stainless steel/ duplex/ nickel alloy. We've been in business of supplying pipes and fittings worldwidely for more than 20years. Now Yuhong as a reliable partner, providing satisfactory solutions in industrial pipeline system field. We are confident that Yuhong can bring you a superior experience compare same as your regular supplier.

Hydraulic Pressure Test

Uses and Applications

1. Common industrial services (Petroleum, chemical, paper, fertilizer, fabric, aviation and nuclear)

2. Fluid, gas and oil industry

3. Heat transmission and pressure service

4. Construction and ornamental

5. Boilers and Heat exchangers

6. Decoration purpose, boiler, auto parts, medical device, food industry, building materials)

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!