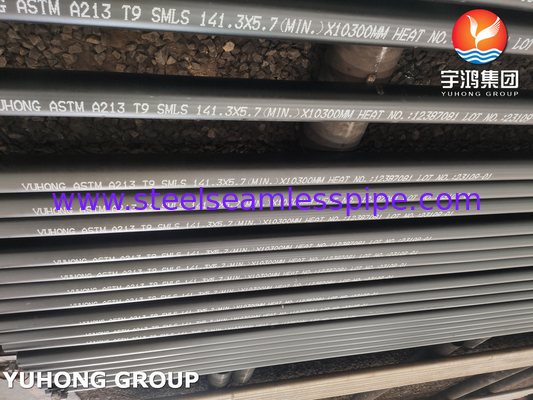

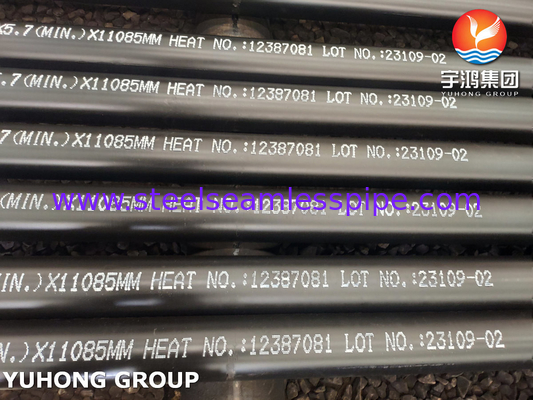

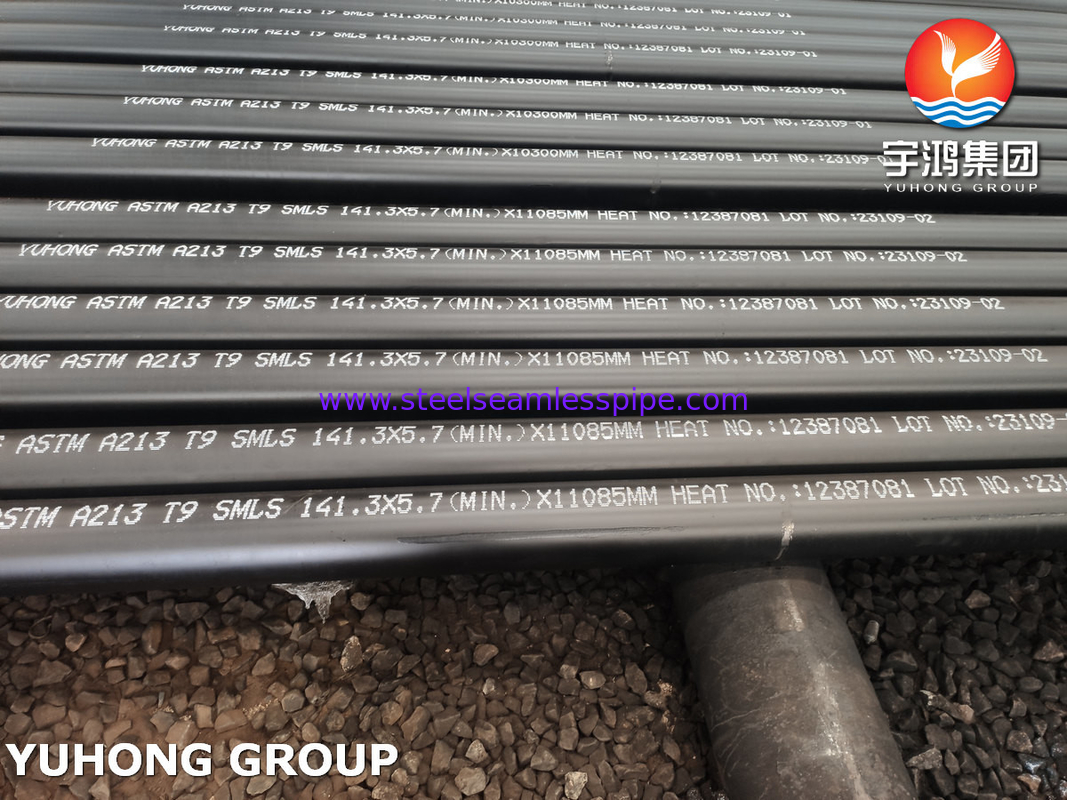

ASTM A213 / ASME SA213 Gr T9 Ferritic Alloy Steel Seamless Tube for Boiler and Heat Exchanger

T9 alloy steel tubes are known for their exceptional heat resistance and strength, making them popular in high-temperature applications. They are seamless tubes, meaning they are manufactured without any weld seams, ensuring uniformity and integrity throughout their length.

The T9 designation signifies the specific alloy composition, which primarily consists of chromium (Cr) and molybdenum (Mo). The addition of these alloying elements enhances the tubes' properties, allowing them to withstand the demanding conditions of high-temperature environments.

Here are some key features and benefits of T9 alloy steel tubes:

1. High-Temperature Stability: T9 tubes can handle sustained operation at elevated temperatures up to 620°C (1150°F) without significant loss in strength or structural integrity.

2. Oxidation and Corrosion Resistance: The composition of T9 alloy steel provides excellent resistance to oxidation, preventing the tubes from deteriorating due to the presence of oxygen at high temperatures. They also exhibit good resistance to corrosion, enhancing their longevity in corrosive environments.

3. Mechanical Strength: T9 alloy steel tubes possess impressive mechanical properties, including high tensile and yield strength, enabling them to withstand high-pressure conditions.

4. Flexibility in Fabrication: T9 tubes can be easily welded, bent, and formed without compromising their structural integrity. This flexibility in fabrication allows for efficient manufacturing and installation processes.

5. Wide Range of Applications: T9 alloy steel tubes find application in various industries, including power generation, petrochemical, oil and gas, automotive, aerospace, and boiler/heat exchanger industries. They are suitable for superheaters, heat exchangers, boilers, pipelines, exhaust systems, and more.

Mechanical Property for ASTM A213 Seamless Steel Tube

| Steel Grade |

Tensile Strength, Mpa |

Yield Strength, Mpa |

Elongation, % |

| ASTM A213 T5 |

Min: 415 |

Min: 205 |

Min: 30 |

| ASTM A213 T9 |

Min: 415 |

Min: 205 |

Min: 30 |

| ASTM A213 T11 |

Min: 415 |

Min: 205 |

Min: 30 |

| ASTM A213 T12 |

Min: 415 |

Min: 205 |

Min: 30 |

| ASTM A213 T22 |

Min: 415 |

Min: 205 |

Min: 30 |

| ASTM A213 T91 |

Min: 415 |

Min: 415 |

Min: 20 |

Chemical Composition for ASTM A213 Seamless Steel Tube

| Steel Grade |

| C |

Mn |

P |

S |

Si |

Cr |

Mo |

V |

| ASTM A213 T5 |

Max: 0.15 |

0.30 - 0.60 |

Max: 0.025 |

Max: 0.025 |

Max: 0.50 |

4.00 - 6.00 |

0.45 - 0.65 |

-- |

| ASTM A213 T9 |

Max: 0.15 |

0.30 - 0.60 |

Max: 0.025 |

Max: 0.025 |

0.25 - 1.00 |

8.00 - 10.00 |

0.90 - 1.10 |

-- |

| ASTM A213 T11 |

0.05 - 0.15 |

0.30 - 0.60 |

Max: 0.025 |

Max: 0.025 |

0.50 - 1.00 |

1.00 - 1.50 |

0.44 -0.65 |

-- |

| ASTM A213 T12 |

0.05 - 0.15 |

0.30 - 0.61 |

Max: 0.025 |

Max: 0.025 |

Max: 0.50 |

0.80 - 1.25 |

0.44 - 0.65 |

-- |

| ASTM A213 T22 |

0.05 - 0.15 |

0.30 - 0.60 |

Max: 0.025 |

Max: 0.025 |

Max: 0.50 |

1.90 - 2.60 |

0.87 - 1.13 |

-- |

| ASTM A213 T91 |

0.08 - 0.12 |

0.30 - 0.60 |

Max: 0.020 |

Max: 0.010 |

0.20 - 0.50 |

8.00 - 9.50 |

0.85 - 1.05 |

0.18 - 0.25 |

| Cb: 0.06 - 0.1 |

N: 0.030 - 0.070 |

Ni: Max: 0.40 |

Al: Max0.04 |

Ti: Max: 0.01 |

Zr: Max 0.01 |

|

|

| Trade Name |

Grade |

UNS # |

Heater Tubes |

| 1 1/4 Chrome |

T11 |

K11597 |

A213 / SA213 |

| 2 1/4 Chrome |

T22 |

K21590 |

A213 / SA213 |

| 5 Chrome |

T5 |

K41545 |

A213 / SA213 |

| 9 Chrome |

T9 |

K90941 |

A213 / SA213 |

| T91 |

T91 |

K90901 |

A213 / SA213 |

| T92 |

T92 |

K92460 |

A213 / SA213 |

Some of the quality tests carried out by us includes

| Corrosion Test |

Conducted only when specially requested by the client |

| Chemical Analysis |

Test done as per required quality standards |

| Destructive / Mechanical Testing |

Tensile | Hardness | Flattening | Flare | Flange |

| Reverse-bend and Re. flat tests |

Carried out in full compliance with relevant standards & ASTM A-450 and A-530 norms, which ensures trouble-free expansion, welding & use at customers end |

| Eddy Current Testing |

Done to detect homogeneities in subsurface by using Digital Flaw-mark Testing System |

| Hydrostatic Testing |

100% Hydrostatic Testing carried out according to ASTM-A 450 norms for checking tube leakage, and biggest pressure we can support 20Mpa/7s . |

| Air Under Pressure Test |

To check any evidence of air leakage |

| Visual Inspection |

After passivation, every single length of tubes & pipes is subjected to thorough visual inspection by trained staff for detecting surface flaws & other imperfections |

Supplementary Testing : Apart from the above mentioned tests, we also carry out on the manufactured products supplementary testing. The tests conducted under this include:

- Eddy Current Testing

- O.P Testing

- Radiography Testing

|

- Corrosion Testing

- Micro Testing

- Macro Testing

|

- IGC Testing

- Ultrasonic testing

- Liquid Penetrate testing

|

Applications

1. Power Generation: T9 alloy steel seamless tubes are used in power plants for applications such as superheater tubes, reheater tubes, and boiler tubes.

2. Petrochemical Industry: These tubes are widely employed in petrochemical plants for processes such as refining, heat exchangers, and cracking units.

3. Oil and Gas Industry: T9 alloy steel seamless tubes are utilized in oil and gas exploration and production activities, including pipelines, drilling operations, and offshore installations.

4. Automotive Industry: The tubes find application in automotive manufacturing for components such as exhaust systems and structural parts where high-temperature resistance and durability are required.

5. Aerospace Industry: T9 alloy steel seamless tubes are employed in the aerospace sector for aircraft engines, gas turbines, and other high-temperature applications.

6. Boiler and Heat Exchanger Industry: These tubes are also utilized in various boiler and heat exchanger systems, providing efficient heat transfer and resistance to elevated temperatures.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!