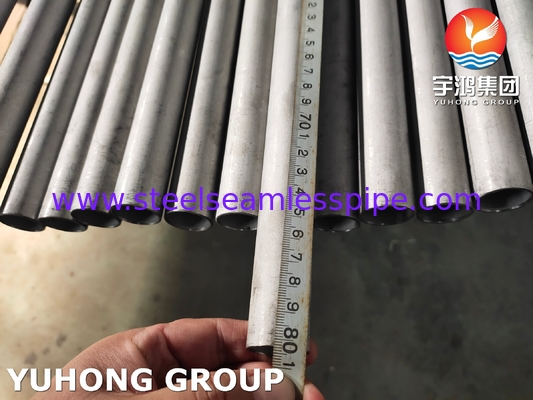

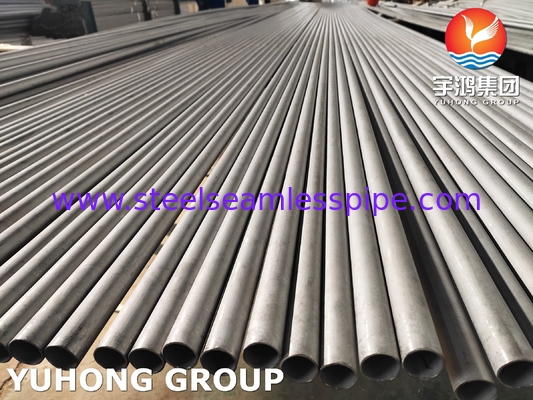

Super Duplex Steel Seamless Tube Heat Exchanger Tube A789 S32750 2507 1.4410 Heat Excjamger ,Condensor Application

Alloy 2507, with UNS number S32750, is a famous super duplex stainless steel. As a member of the duplex stainless steel family, it is a two-phase alloy based on the iron-chromium-nickel system with a mixed structure of about equal proportions of austenite and ferrite. Due to the duplex phase balance, Alloy 2507 exhibits excellent resistance to general corrosion like that of austenitic stainless steels with similar alloying elements. Besides, it possesses higher tensile and yield strengths as well as significantly better chloride SCC resistance than its austenitic counterparts while maintaining better impact toughness than the ferritic counterparts.

ASTM A789 ASME SA789 Common Steel Grades:

ASTM A789 S31803 is a duplex stainless steel containing 21% - 23% chromium, 2.5% - 3.5% molybdenum, 4.5-6.5% nickel and 0.08% - 0.20% nitrogen alloy. In addition to its high strength characteristics, it also has local stress corrosion resistance.S31803 and S32205 are standard duplex stainless steels. A nitrogen and molybdenum reinforced AUSTENITIC FERRITIC duplex stainless steel with general corrosion resistance similar to 904L, but its yield strength is almost twice that of austenitic stainless steel.

ASTM A789 S32205

ASTM A789 S32205 is a duplex stainless steel containing 22% - 23% chromium, 3.0% - 3.5% molybdenum, 4.5-6.5% nickel and 0.08% - 0.20% nitrogen alloy. Alloy 2205 has better pitting and crevice corrosion ability than 316L or 317L austenitic stainless steel pipe in almost all corrosion media. 2101 is a low nickel and barren duplex stainless steel. Compared with 300 series stainless steel, it has excellent strength and chloride stress corrosion cracking resistance.

ASTM A789 S32750

ASTM A789 S32750 is a super duplex stainless steel containing 24% - 26% chromium, 3% - 5% molybdenum and 6% - 8% nickel. The super duplex steel has good pitting and crevice corrosion resistance. 2507 (PREN 40-45), compared with 25cr brand, contains 25-26cr, Mo and N increased. A super AUSTENITIC FERRITIC duplex stainless steel with special strength and corrosion resistance, it is an ideal choice for chemical process, petrochemical and seawater applications.

X2crnimon25-7-4, 1.4410, SAF2507 and F53 are equivalent grades.

ASTM A789 S32760

ASTM A789 S32750 is a super duplex stainless steel containing 24% - 26% chromium, 3% - 4% molybdenum and 6% - 8% nickel. F55 and 1.4501 are equivalent grades.

ASTM A789 ASME SA789 Seamless Tube Chemical Composition

| UNS Number |

Type |

C |

Mn |

P |

S |

Si |

Cr |

Ni |

Mo |

N |

Cu |

Other |

| Duplex Grades |

% |

| S31200 |

… |

0.03 |

2 |

0.045 |

0.03 |

1 |

24.0-26.0 |

5.5-6.5 |

1.20-2.00 |

0.14-0.20 |

… |

… |

| S31260 |

… |

0.03 |

1 |

0.03 |

0.03 |

0.75 |

24.0-26.0 |

5.5-7.5 |

2.5-3.5 |

0.10-0.20 |

0.20-0.80 |

W 0.10-0.20 |

| S31803 |

… |

0.03 |

2 |

0.03 |

0.02 |

1 |

21.0-23.0 |

4.5-6.5 |

2.5-3.5 |

0.08-0.20 |

… |

|

| S32001 |

… |

0.03 |

4.0-6.0 |

0.04 |

0.03 |

1 |

22.0-23.0 |

1.00-3.00 |

0.6 |

0.05-0.17 |

1 |

|

| S32205 |

2205 |

0.03 |

2 |

0.03 |

0.02 |

1 |

19.5-21.5 |

4.5-6.5 |

3.0-3.5 |

0.14-0.20 |

… |

|

| S32304 |

2304 |

0.03 |

2.5 |

0.04 |

0.03 |

1 |

21.5-24.5 |

3.0-5.5 |

0.05-0.60 |

0.05-0.20 |

0.05-0.60 |

|

| S32520 |

… |

0.03 |

1.5 |

0.035 |

0.02 |

0.8 |

24.0-26.0 |

5.5-8.0 |

3.0-4.0 |

0.20-0.35 |

0.50-2.00 |

|

| S32550 |

255 |

0.04 |

1.5 |

0.04 |

0.03 |

1 |

24.0-27.0 |

4.5-6.5 |

2.9-3.9 |

0.10-0.25 |

1.5-2.5 |

|

| S32750 |

2507 |

0.03 |

1.2 |

0.035 |

0.02 |

0.8 |

24.0-26.0 |

6.0-8.0 |

3.0-5.0 |

0.24-0.32 |

0.5 |

|

| S32760 |

… |

0.03 |

1 |

0.03 |

0.01 |

1 |

24.0-26.0 |

6.0-8.0 |

3.0-4.0 |

0.20-0.30 |

0.50-1.00 |

W 0.50-1.0 |

| S32900 |

329d |

0.06 |

1 |

0.04 |

0.03 |

0.75 |

23.0-28.0 |

2.5-5.0 |

1.0-2.0 |

… |

… |

|

| S32950 |

… |

0.03 |

2 |

0.035 |

|

|

|

|

|

|

|

|

A Maximum, unless a range or minimum is indicated. Where ellipses (…) appear in this table, there is no minimum and analysis for the element need not be determined or reported.

B Designation established in accordance with Practice E527 and SAE J1086.

C % Cr + 3.3 × % Mo + 16 × % N $ 41.

D % Cr + 3.3 × % Mo + 16 × % N $ 40.

ASTM A789 ASME SA789 Seamless Tube Mechanical

| Grade |

Tensile Strength, min., ksi [MPa] |

Yield Strength, min., ksi [MPa] |

Elongation in 2 in., or 50mm, min, % |

Hardness, Max Brinell |

| S31803 |

90 [620] |

65 [450] |

25 |

290 |

| S32205 |

95 [655] |

70 [485] |

25 |

290 |

| S31500 |

92 [630] |

64 [440] |

30 |

290 |

| S32550 |

110 [760] |

80 [550] |

15 |

297 |

| S31200 |

100 [690] |

65 [450] |

25 |

280 |

| S31260 |

100 [690] |

65 [450] |

25 |

290 |

| S32001 |

90 [620] |

65 [450] |

25 |

290 |

| S32304 |

100 [690] |

65 [450] |

25 |

290 |

| S32750 |

116 [800] |

80 [550] |

15 |

310 |

| S32760 |

109 [750] |

80 [550] |

25 |

300 |

| S32950 |

100 [690] |

70 [480] |

20 |

290 |

| S32520 |

112 [770] |

80 [550] |

25 |

310 |

For tubing smaller than 1⁄2 in. [12.7 mm] in outside diameter, the elongation values given for strip specimens in Table 4 shall apply. Mechanical property requirements do not apply to tubing smaller than 1⁄8 in. [3.2 mm] in outside diameter or with walls thinner than 0.015 in. [0.4 mm].

Prior to A789/A789M–04, the values for S32003 were 90 ksi tensile strength and 65 ksi yield strength.

Duplex Steel Grades Comparison Chart

| China GB |

ISO Unified Digital Code |

ASTM / ASME |

UNS code |

EN Code |

Company Commercial Grade |

| 022Cr23Ni4MoCuN |

S23043 |

S32304 |

S32304 |

1.4362 |

SAF2304 (Sandvik) |

| 022Cr22Ni5Mo3N |

S22253 |

S31803 |

S31803 |

1.4462 |

– |

| 022Cr23Ni5Mo3N |

S22053 |

S32205 |

S32205 |

1.4462 |

SAF2205 (Sandvik) |

| 022Cr25Ni7Mo4N |

S25073 |

S32750 |

S32750 |

1.441 |

SAF2507(Sandvik) |

| 022Cr25Ni7Mo3WCuN |

S22583 |

S31260 |

S31260 |

– |

– |

| 03Cr25Ni6Mo3Cu2N |

S25554 |

S32550 |

S32550 |

1.4507 |

UR52+ |

| 022Cr25Ni7Mo4WCuN |

S27603 |

S32760 |

S32760 |

1.4501 |

Zeron100 |

| 00Cr27Ni7Mo5N |

– |

S32707 |

S32707 |

– |

SAF2707(Sandvik) |

ASTM A789 Seamless Tubes Heat Treatment

All tubes shall be furnished in the heat-treated condition in accordance with the procedures shown in Table 2. For seamless tubes, as an alternate to final heat treatment in a continuous furnace or batch-type furnace, immediately follow- ing hot forming while the temperature of the tubes is not less than the specified minimum solution treatment temperature, tubes may be individually quenched in water or rapidly cooled by other means.

| UNS Designation |

Temperature |

Quench |

| S31803 |

1870-2010 °F [1020-1100°C] |

Rapid cooling in air or water |

| S32205 |

1870-2010 °F [1020-1100°C] |

Rapid cooling in air or water |

| S31500 |

1800-1900 °F [980-1040°C] |

Rapid cooling in air or water |

| S32550 |

1900 °F [1040°C] min. |

Rapid cooling in air or water |

| S31200 |

1920-2010 °F [1050-1100°C] |

Rapid cooling in water |

| S31260 |

1870-2010 °F [1020-1100°C] |

Rapid cooling in water |

| S32001 |

1800-1950 °F [982-1066°C] |

Rapid cooling in air or water |

| S32003 |

1850-2050 °F [1010-1120°C] |

Rapid cooling in air or water |

| S32101 |

1870 °F min |

Quenched in water or Rapidly cooling in other means |

| S32202 |

1870-1975 °F [1020-1080°C] |

Rapid cooling in air or water |

| S32506 |

1870-2050 °F [1020-1120°C] |

Rapid cooling in air or water |

| S32304 |

1700-1920 °F [925-1050°C] |

Rapid cooling in air or water |

| S32750 |

1880-2060 °F [1025-1125°C] |

Rapid cooling in air or water |

| S32760 |

2010-2085 °F [1100-1140°C] |

Rapid cooling in air or water |

| S32950 |

1820-1880 °F [990-1025°C] |

Rapid cooling in water |

| S32520 |

1975-2050 °F [1080-1120°C] |

Rapid cooling in air or water |

ASTM A789 Stainless Steel Tubing Tolerances

| Outside |

OD Tolerance, |

Average Wall |

Minimum Wall |

Minimum Wall |

Cut Length, In. |

Cut Length, In. |

Thin Walled |

| Diameter, In. |

In. [Mm] |

In Wall Thickness,% |

In Wall Thickness, |

In Wall Thickness, |

[Mm], Over |

[Mm], Under |

Tubes |

| [Mm] |

|

|

%, Over |

%, Under |

|

|

|

| Up To 1⁄2 [12.7], Excl |

±0.005 [0.13] |

±15 |

30 |

0 |

1⁄8 [3] |

0 |

… |

| 1⁄2 To 11⁄2 [12.7 To 38.1], Excl |

±0.005 [0.13] |

±10 |

20 |

0 |

1⁄8 [3] |

0 |

Less Than 0.065 In. [1.6 Mm] Specified |

| 11⁄2 To 31⁄2 [38.1 To 88.9], Excl |

±0.010 [0.25] |

±10 |

20 |

0 |

3⁄16 [5] |

0 |

Less Than 0.095 In. [2.4 Mm] Specified |

| 31⁄2 To 51⁄2 [88.9 To 139.7], Excl |

±0.015 [0.38] |

±10 |

20 |

0 |

3⁄16 [5] |

0 |

Less Than 0.150 In. [3.8 Mm] Specified |

| 51⁄2 To 8 [139.7 To 203.2], Incl |

±0.030 [0.76] |

±10 |

20 |

0 |

3⁄16 [5] |

0 |

Less Than 0.150 In. [3.8 Mm] Specified

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!