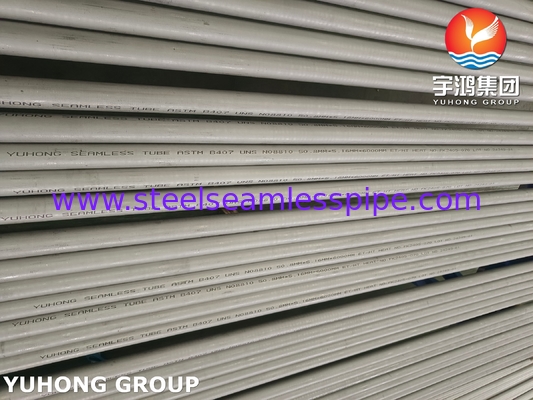

ASTM A407 N08810 Heat Exchanger Tube Chemical Composition

| UNS Designation |

Ni |

Cu |

Iron |

Mn |

C |

Cr |

Ti |

Al |

| N08810 |

0.30–0.35 |

0.75 |

39.5 |

1.5 |

0.05–0.10 |

19.0-23.0 |

0.15-0.60 |

0.15-0.60 |

ASTM B407 N08810 Heat Exchanger Tube Application

Tubes are used in extreme environments:

- Petrochemical: Ethylene furnace coils, reformer tubes, pyrolysis units.

- Power Generation: Superheater tubes, heat exchangers, boiler components.

- Nuclear: Steam generator tubing, heat exchangers (resists chloride stress corrosion).

- Industrial Furnaces: Radiant tubes, muffles, conveyor systems.

- Chemical Processing: Acid production, catalyst support grids.

| Application |

Primary Challenge |

800H’s Advantage |

| Ethylene cracking |

Carburization + creep |

Controlled carbon + Ni/Cr matrix stability |

| Nuclear steam gens |

SCC in chlorides |

>30% Ni content prevents cracking |

| Reformer tubes |

Hydrogen embrittlement |

Stable austenitic structure |

| Radiant furnace tubes |

Cyclic oxidation/carburizing |

Al/Ti oxide layer formation |

ASTM B407 N08810 Heat Exchanger Tube Strength & Mechanical Properties

Tensile Strength: ≥500 MPa (72.5 ksi)

Yield Strength (0.2% offset): ≥170 MPa (25 ksi)

Elongation: ≥30%

- Elevated Temperature (650°C / 1200°F):

Tensile Strength: ~380 MPa (55 ksi)

Creep Rupture Strength: Excellent (e.g., 10,000 hrs at 815°C: ~20 MPa)

- Key Strengths: Retains structural integrity under thermal cycling/stress; superior to standard stainless steels (e.g., 304/316) above 600°C.

- High-Temperature Performance: Outperforms stainless steels in creep strength above 600°C.

- Corrosion Resistance: Resists oxidation, carburization, and reducing sulfur atmospheres.

- Fabricability: Weldable (using ENiCrFe-3 filler) and formable with standard methods.

- Cost-Effective: More economical than high-nickel alloys (e.g., Inconel) for moderate temperatures.

ASTM B407 N08810 Heat Exchanger Tube FAQ

1. What distinguishes Incoloy 800H from standard Incoloy 800?

800H has a higher carbon content (0.05–0.10% vs. 0.03% max in 800) for superior creep resistance at >600°C.

It undergoes solution annealing at ≥1100°C to achieve an ASTM No. 5 or coarser grain size, optimizing high-temperature strength.

2. What temperatures can Incoloy 800H tubes handle?

Continuous Service: Up to 815°C (1500°F).

Short-Term Exposure: Up to 950°C (1740°F).

Critical Note: For >900°C, Incoloy 800HT (Ti/Al-controlled) is preferred for enhanced stability.

3. Is welding 800H tubes difficult?

Weldable via:

TIG/GTAW with ERNiCr-3 (FM 82) filler.

SMAW with ENiCrFe-3 electrodes.

Post-Weld Requirement: Solution annealing (1100–1175°C) is essential to restore corrosion/creep resistance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!