- YUHONG brand goods have been already exported to more than 85 countries With more than 35 years' experience, because of strict quality control policy, excellent sales service, delivery on time. YUHONG won more and more new clients and got more and more repeat orders from old clients, in YUHONG People's mind: Quality is First Important!

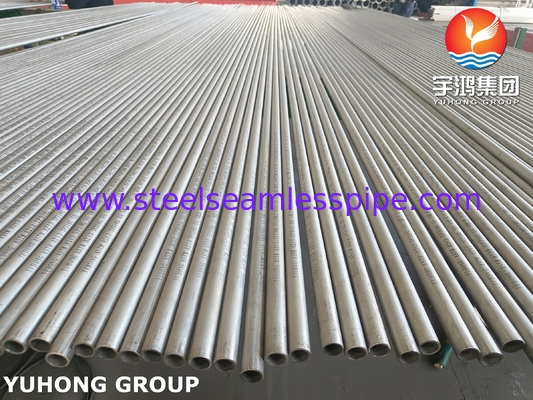

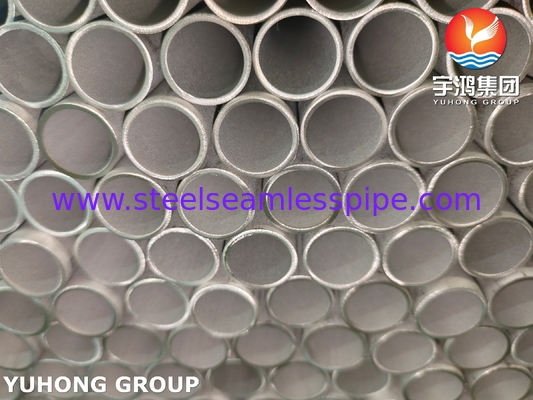

ASME SA213 TP316 (UNS S31600) Stainless Seamless Tube for Heat Exchanger and Boiler

ASME SA213 TP316 (UNS S31600) is a seamless austenitic stainless steel tube specifically designed for high-temperature service in heat exchangers, boilers, and superheaters. It offers excellent corrosion resistance, high-temperature strength, and oxidation resistance due to its molybdenum-enhanced composition. This material complies with the ASME Boiler and Pressure Vessel Code, ensuring reliability in critical thermal applications.

1.Chemical & Mechanical Properties

| ASME SA213 TP316 Chemical Composition (%) |

| C |

Mn

|

P |

S |

Si

|

Cr |

Ni |

Mo |

N |

| ≤0.08% |

≤2.00% |

≤0.045% |

≤0.030% |

≤1.00% |

16.0%~18.0% |

10.0%~14.0% |

2.00%~3.00% |

/ |

Mechanical Properties

| Property |

Standard Value (Annealed) |

| Tensile Strength |

≥515 MPa (75 ksi) |

| Yield Strength |

≥205 MPa (30 ksi) |

| Elongation |

≥35% |

| Hardness |

≤ HRB 90(192HBW) |

2. Key Adventages

- Superior Corrosion Resistance

Molybdenum-enhanced (2%~3% Mo) resists pitting and crevice corrosion in chloride environments.

High chromium-nickel content resists acids, alkalis, and oxidation in harsh conditions (e.g., chemical, marine).

- High-Temperature & Pressure Performance

Maintains strength at high temperatures with excellent oxidation/creep resistance for boilers & heat exchangers.

The maximum temperature resistance can reach 1040℃ (1900℉).

- Excellent Fabrication & Weldability

Seamless cold/hot forming allows bending/flaring without cracking.

Compatible with TIG/MIG welding, no post-weld heat treatment required.

- Long Service Life & Low Maintenance

Smooth seamless interior minimizes scaling, reducing maintenance costs.

Long-term cost efficiency due to extended service life.

3. Key Applications

-

Power Generation Industry

Power station boiler systems: Superheaters, reheaters, and main steam pipes for supercritical/ultra-supercritical boilers.

Nuclear power equipment: Auxiliary cooling systems and steam generator heat transfer tubes.

Refining units: Pipes for high-temperature/pressure reactors (e.g., catalytic cracking, hydrocracking).

Chemical heat exchangers: Shell-and-tube/plate heat exchanger cores resistant to acids, alkalis, and salts.

Desalination systems: Chloride-resistant pipes for MSF and RO plants.

Marine propulsion systems: Exhaust pipes for gas turbines, fuel boiler tubes.

-

Environmental & New Energy

Waste-to-energy plants: Flue gas heat recovery pipes with high-temperature corrosion resistance.

Hydrogen energy equipment: Hydrogen-resistant pipes for electrolyzers.

Stainless Steel Seamless Tube Testing

- DFARS compliant

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- 100% Radiography Test Report---If welded type

- Raw Materials Certificate

- Third Party Inspection Report

- Fumigation Certificates

- Heat Treatment Charts

- HS Code Commercial Invoice

- Form A for Generalized System of Preferences (GSP)

- Manufacturer Test Certificate

- Moisture testing

- Surface roughness measurement

- Laboratory Test Certificate from Govt. Approved Lab

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!