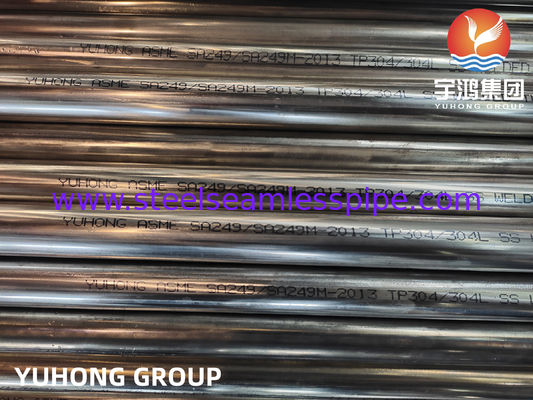

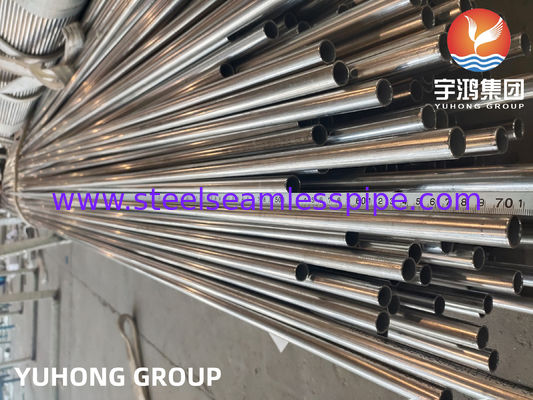

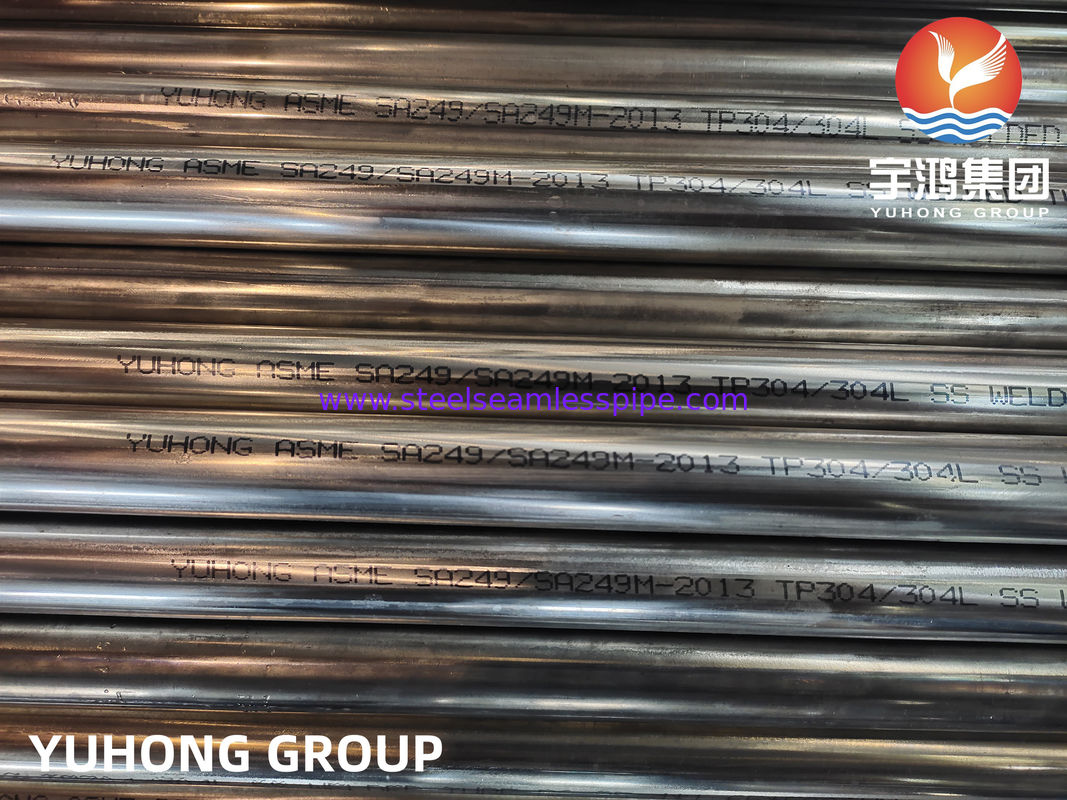

1. Introduction to ASME SA249 Standard and Material Grades

The ASME SA249 standard, developed by the American Society of Mechanical Engineers (ASME), specifically covers the requirements for welded austenitic stainless steel tubes used in boilers, superheaters, heat exchangers, and condensers. This standard ensures that the tubes meet rigorous quality and performance requirements for critical high-temperature and pressure applications.

The TP304 and TP304L grades are among the most widely used austenitic stainless steels globally. While they share many characteristics, the key difference lies in their carbon content:

- TP304: Maximum carbon content of 0.08%

- TP304L: Maximum carbon content of 0.03% (the "L" denotes "Low carbon")

Dual-grade certification indicates that the material meets the chemical and mechanical properties requirements of both grades, offering enhanced flexibility for various applications.

2. ASME SA249 TP304/304L Stainless Steel Welded Tube Chemical Composition Requirements

The chemical composition of ASME SA249 TP304/304L welded tubes must conform to the following specifications:

| Element |

TP304 Requirements |

TP304L Requirements |

Dual Certification Implications |

| Carbon (C) |

≤0.08% |

≤0.03% |

Must meet the stricter ≤0.03% limit |

| Manganese (Mn) |

≤2.0% |

≤2.0% |

Must meet ≤2.0% |

| Silicon (Si) |

≤1.00% |

≤1.00% |

Must meet ≤1.00% |

| Phosphorus (P) |

≤0.045% |

≤0.045% |

Must meet ≤0.045% |

| Sulfur (S) |

≤0.030% |

≤0.030% |

Must meet ≤0.030% |

| Chromium (Cr) |

18.00-20.00% |

18.00-20.00% |

Must meet 18.00-20.00% |

| Nickel (Ni) |

8.00-11.00% |

8.00-12.00% |

Typically adjusted to 8.00-12.00 |

3. SA249 TP304/304L Welded Tube Mechanical Properties and Performance Characteristics

| Property |

TP304 Requirements |

TP304L Requirements |

Notes |

| Tensile Strength |

≥515 MPa |

≥485 MPa |

TP304L typically has slightly lower strength |

| Yield Strength |

≥205 MPa |

≥170 MPa |

TP304L has lower yield strength |

| Elongation |

≥35% |

≥35% |

Both maintain excellent ductility |

| Hardness (HRC) |

<90 |

<90 |

Similar hardness characteristics |

4. SA249 TP304/304L Welded Tube Heat Treatment and Quality Assurance

All tubes undergo solution annealing heat treatment:

- Heating to ≥1040°C in a protective atmosphere (bright annealing)

- Holding at temperature for sufficient time to dissolve carbides

- Rapid cooling via water quenching or other methods to prevent carbide precipitation

This process ensures optimal corrosion resistance and mechanical properties.

Manufacturing follows rigorous quality control procedures:

- Raw material verification: Chemical composition confirmation

- Process control: Monitoring of welding parameters

- Non-destructive testing (NDT): Includes X-ray examination, ultrasonic testing, and eddy current testing

- Destructive testing: Periodic tests of mechanical properties

- Final inspection: Dimensional verification, visual examination, and hydrostatic testing when required

5. ASME SA249 TP304/304L welded tubes Applications:

- Power Generation Equipment Boiler tubes: For steam generation in fossil fuel and biomass power plants.

Superheater tubes: For increasing steam temperature beyond saturation point.

Heat exchanger tubes: For various heat transfer applications in power cycles.

- Process Industries Chemical processing: Handling corrosive chemicals, acids, and solvents.

Petroleum refining: Transferring hydrocarbons and process fluids.

Pharmaceutical manufacturing: Maintaining product purity in sterile processes.

- Other Applications Food and beverage processing: Meeting hygiene and cleanability requirements.

Nuclear power: Selected applications where corrosion resistance is crucial.

Marine applications: Heat exchangers for shipboard systems.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!