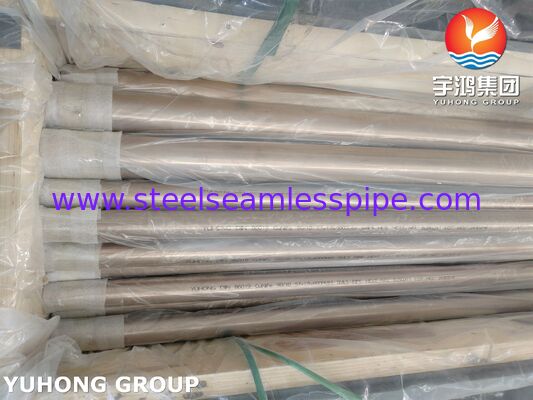

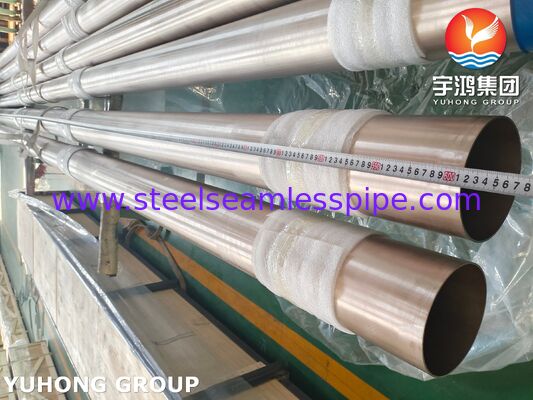

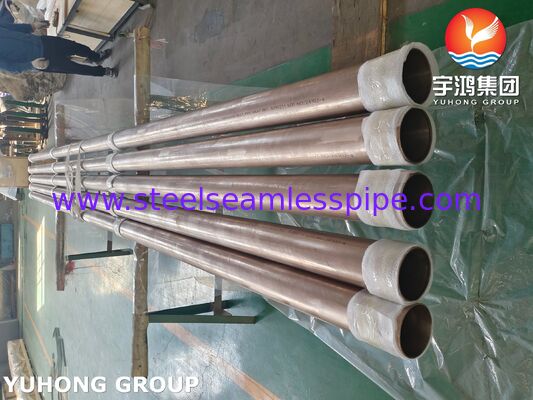

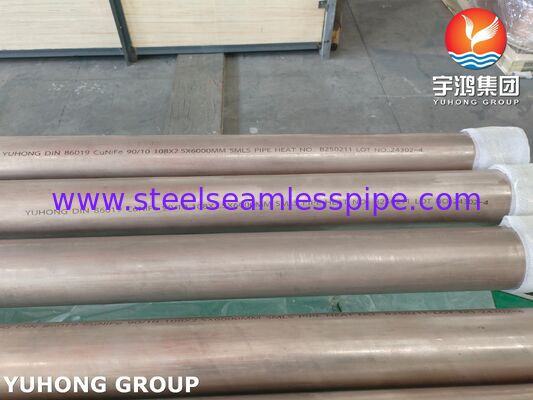

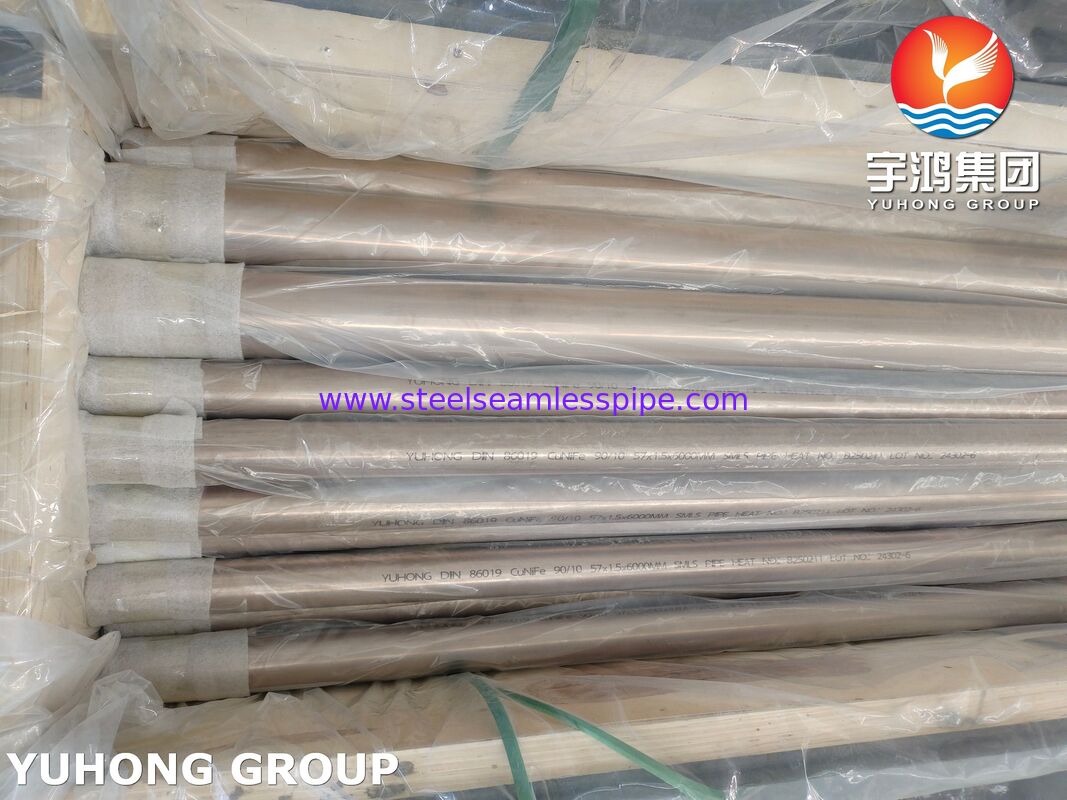

DIN 86019 CuNiFe 90/10 (C70600) Nickel Copper Alloy Steel Seamless Pipe

Description

"DIN 86019 CuNiFe 90/10" refers to a high-performance seamless copper-nickel alloy pipe manufactured strictly according to German marine and marine technology standards.

Its core material is 90/10 copper-nickel alloy (C70600), which, with approximately 90% copper, 10% nickel, and a small amount of iron, possesses excellent resistance to seawater corrosion and marine organism adhesion.

This product utilizes a seamless manufacturing process, ensuring the pipe's uniformity and high strength. It is specifically designed for demanding applications in marine seawater cooling systems, offshore platforms, and desalination plants, making it one of the standard solutions for corrosion-resistant pipelines in marine engineering.

Chemical composition of CuNiFe 90/10 copper nickel alloys

|

Element

|

Content (%)

|

|

Cu

|

88.7

|

|

Fe

|

1.3

|

|

Ni

|

10.0

|

Mechanical Structure Of CuNiFe 90/10 Copper Nickel Tube

| Density |

Melting Point |

Yield Strength (0.2%Offset) |

Tensile Strength |

Elongation |

| 8.1 g/cm3 |

1443 °C (2430 °F) |

Psi – 35,000, MPa – 241 |

Psi -80,000, MPa -551 |

30 % |

| Equivalencies Copper Nickel (90/10) Pipe: |

| KS D5301 |

C7060T |

| JIS H3300 |

| ASTM B111 |

C70600 |

| ASTM B466 |

C70600 |

| BS2871 {PART2} |

CN102 |

| AS1752 |

C70600 |

| DIN17664 |

CuNi10Fe 1Mn |

| DIN 86019 WL2.1972 |

CuNi10Fe 1.6Mn |

| EEMUA 144 |

7060X |

| MIL-T-16420K |

706 |

| EN12449 |

CW352H

|

Applications

Ships and Vessels:

Used as main piping in seawater cooling systems, fire suppression systems, and ballast and bilge water supply lines. Its excellent corrosion resistance ensures long-term reliable system operation.

Offshore Oil and Gas Platforms:

Used in seawater injection systems, cooling water piping, and various process pipelines. Resistant to harsh marine corrosive environments.

Seawater Desalination Plants:

Used as process piping in heat exchanger tubes and multi-stage flash evaporators. A typical application of its corrosion resistance and biofouling resistance.

Coastal Power Plants and Facilities:

Used as condenser cooling water piping, ensuring service life under continuous seawater erosion.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!