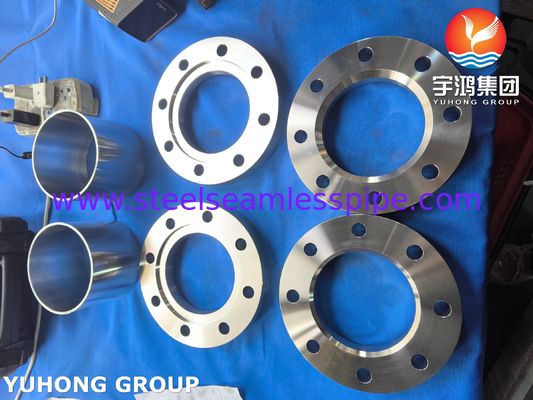

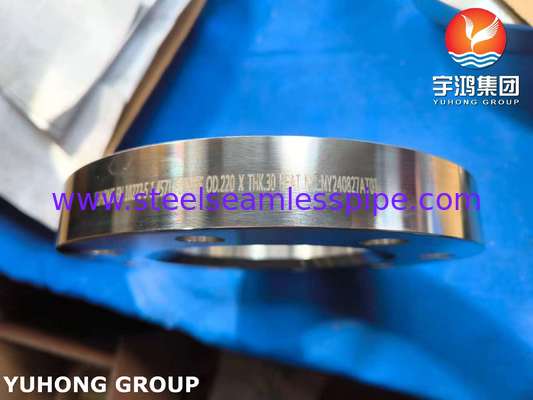

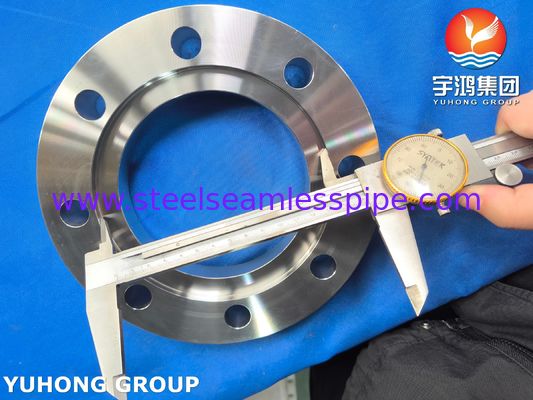

STAINLESS STEEL FLANGE,EN10222-5 1.4571,316Ti,FORGED RING, FLANGE

YUHONG GROUP deal with Austenitic Stainless Steel, Nickel Alloy Steel(Hastelloy , Monel, Inconel, Incoloy ) seamless and welded pipe and tube already more than 25 years, every year sell more than 80000 tons of steel pipe and tube. Our client already cover more than 45 countries, Like Italy, UK, Gernmany, USA, Canada, Chile, Colombia, Saudi Arabia, Korea, Singapore, Austrial, Poland, France , ....And our group branch company and factory have been already approved by :ABS, DNV, GL, BV, PED 97/23/EC, AD2000-WO, GOST9941-81, CCS, TS, CNNC, ISO9001-2008, ISO 14001-2004.

EN 10222-5: Forgings for pressure purposes – Part 5: Weldable fine grain steels with high proof strength.

EN 10222-5 is a critical material specification for high-performance steel forgings.** When you see it referenced, it means the component is made from a premium-grade, high-strength, tough, and weldable steel designed to safely withstand high pressures, low temperatures, and demanding cyclic loads in critical applications like offshore platforms, power plants, and chemical processing facilities.

Chemical Composition of Steel Grade EN10222-5 1.4571 (316Ti)

| Element |

Requirement (%) |

Notes |

| Carbon (C), max |

0.08 |

|

| Silicon (Si), max |

1 |

|

| Manganese (Mn), max |

2 |

|

| Phosphorus (P), max |

0.045 |

|

| Sulfur (S), max |

0.015 |

Note: "b" likely denotes a special condition |

| Chromium (Cr) |

16.5 - 18.5 |

|

| Molybdenum (Mo) |

2.00 - 2.50 |

|

| Nickel (Ni) |

10.5 - 13.5 |

|

| Nitrogen (N) |

- |

Not specified |

| Other Elements |

Ti: 5 × C% min to 0.70 max |

Titanium stabilization

|

When to Choose EN 10222-5 1.4571 Over Common Alternatives?

Vs. Standard 316/316L Plate or Bar Flanges:Choose 1.4571 when the system will be welded and exposed to corrosive media, or will see service temperatures in the sensitization range. For low-temperature, non-welded, or mildly corrosive service, 316L may suffice.

Vs. 321 (1.4541):Both are stabilized (321 uses Titanium, 347 uses Niobium). 1.4571 (316Ti) generally has better overall corrosion resistance and higher creep strength than 321. 316Ti is often the preferred choice for more aggressive chemical environments.

Vs. Duplex Stainless Steels (e.g., 1.4462 / 2205): Duplex steels offer much higher strength and excellent chloride stress corrosion cracking (SCC) resistance. Choose 1.4571 if you need superior resistance to reducing acids, better formability/weldability (though 1.4571 is also very weldable), or are in an application where duplex's phase balance could be compromised.

Test Certificate

Manufacturer Test Certificate as per EN 10204 / 3.1B

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!