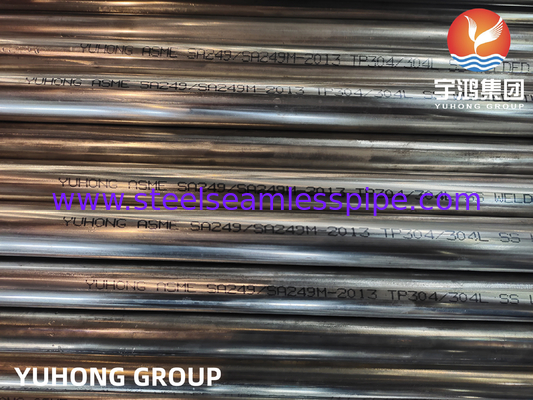

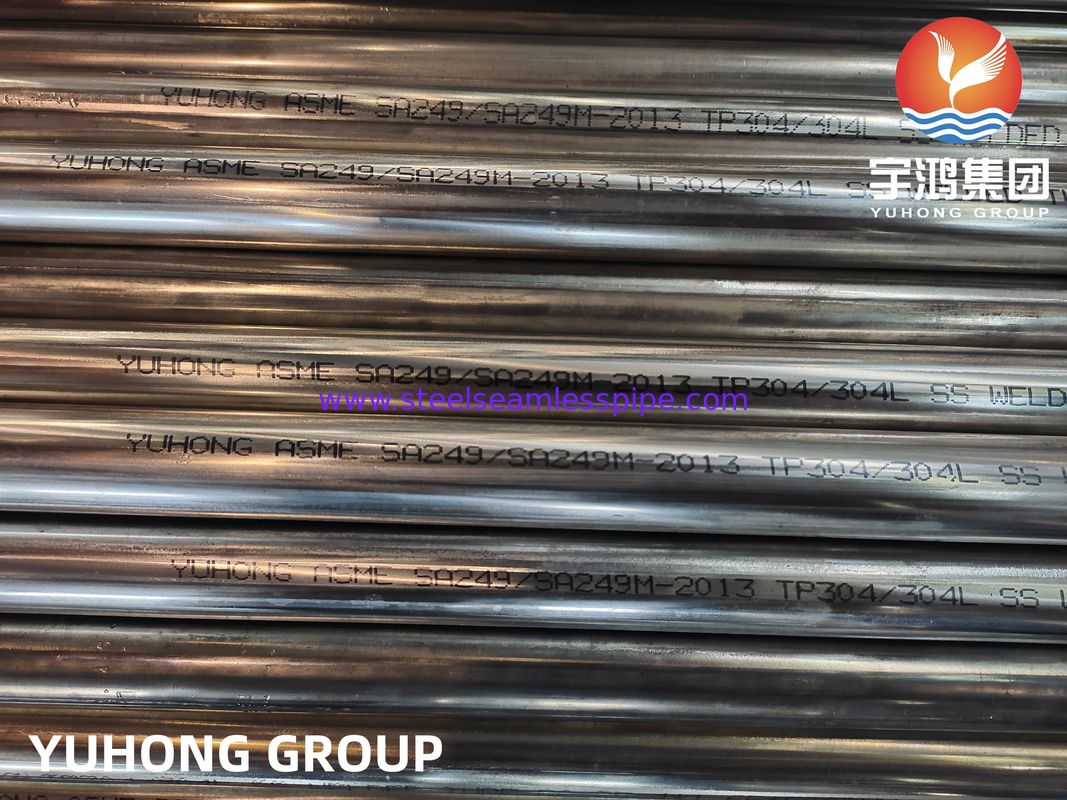

ASME SA249 TP304/304L 1.4301/1.4307 Stainless Steel Bright Annealed Welded Tube

Overview:

TP304/304L bright annealed welded tubes are a type of stainless steel tubing widely used due to their excellent corrosion resistance, strength, and versatility. Made from the 304 and 304L stainless steel grades, these tubes cater to diverse applications, particularly in industries like chemical processing, food and beverage, pharmaceuticals, and petrochemicals.

The unique characteristic of bright annealing involves heating the steel in an inert atmosphere, which aids in achieving a smooth, reflective surface finish while preventing oxidation. This process enhances the aesthetic quality of the tubes and improves their corrosion resistance by eliminating scales and oxides that could form during conventional annealing.

TP304 is known for its superior mechanical properties, including tensile strength and yield strength, making it ideal for high-temperature applications. TP304L, with its lower carbon content, offers enhanced weldability and reduced susceptibility to intergranular corrosion, making it suitable for applications requiring extensive welding.

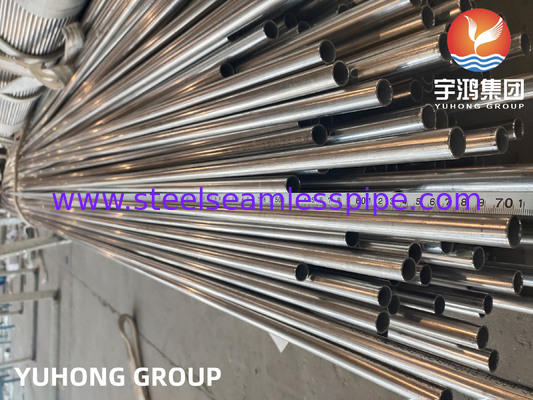

These tubes are available in various sizes and thicknesses and can be customized based on specific requirements. They exhibit excellent formability, making them easy to work with in various configurations, including bends and complex shapes. The welding process typically uses techniques such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) to ensure strong, high-quality joints.

Additionally, TP304/304L tubes are compliant with various industry standards, including ASTM A249 and ASTM A269, assuring customers of their reliability and quality. They can be utilized in applications ranging from heat exchangers and pressure vessels to pipe fittings and structural components.

Specification:

| Standard |

ASTM A249 & Its equivalent ASME, DIN & EN Standard |

| Grades |

TP304/304L; 1.4301/1.4307 |

| Type |

Straight welded tube |

| Outer Diameter |

1/4'' to 2'' or custom size |

| Wall Thickness |

BWG25;BWG22;BWG20;BWG18;BWG16;BWG14;BWG12;BWG10 |

| Length |

Upto 6 meters or custom cut lengths |

| Delivery Condition |

Bright Annealed |

| Ends |

Plain End, Beveled End |

| Other Testing |

Product Analysis, Eddy Current Test, Hydrostatic Test, Ultrasonic Test, Flattening Test, Hardness Test, Tensile Test etc. |

| Dimension |

All Pipe & Tube Is Manufactured and Inspected / Tested to the Relevant standards including ASTM and ASME |

| Packing |

Plywood case/Woven bag in bundle |

Chemical Composition:

| Grade |

UNS |

C |

Mn |

P |

S |

Si |

Cr |

Ni |

| TP304 |

S30400 |

0.08 max |

2.00 max |

0.045 max |

0.03 max |

1.00 max |

18.0-20.0 |

8.0-11.0 |

| TP304L |

S30403 |

0.03 max |

2.00 max |

0.045 max |

0.03 max |

1.00 MAX |

18.0-20.0 |

8.0-12.0 |

Mechanical Properties:

| Grade |

UNS |

Tensile Strength

min, ksi (MPa)

|

Yield Strength

min, ksi (MPa) |

Elongation in 2 in.

or 50mm, min (%) |

Rockwell Hardness |

| TP304 |

S30400 |

75(515) |

30(205) |

35 |

90HRB |

| TP304L |

S30403 |

70(485) |

25(170) |

35 |

90HRB |

Applications:

1. Chemical Processing:

- Suitable for handling a variety of chemicals, especially in environments where resistance to corrosion is critical.

2. Food and Beverage Industry:

- Widely used in food processing equipment due to its hygienic properties.

3. Pharmaceuticals:

- Ideal for equipment such as reactors and heat exchangers, ensuring purity and compliance with stringent sanitary standards.

4. Oil and Gas:

- Utilized in pipelines and various components that require robustness and resistance to harsh environments.

5. Power Generation:

- Employed in systems that require high strength and corrosion resistance.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!