ASTM A182 F304/304L,F316/F316L Stainless Steel Flanges SORF / SOFF / WNRF Type AD2000 Certification ISO Certificate

YUHONG SPECIAL STEEL deal with Austenitic Stainless Steel, Nickel Alloy Steel(Hastelloy , Monel, Inconel, Incoloy ) seamless and welded pipe and tube already more than 25 years, every year sell more than 20000 tons of Stainless steel&Duplex steel&Alloy steel material. Our client already cover more than 45 countries, Like Italy, UK, Gernmany, USA, Canada, Chile, Colombia, Saudi Arabia, Korea, Singapore, Austrial, Poland, France , ....And our group branch company and factory have been already approved by :ABS, DNV, GL, BV, PED 97/23/EC, AD2000-WO, GOST9941-81, CCS, TS, CNNC, ISO9001-2008, ISO 14001-2004.

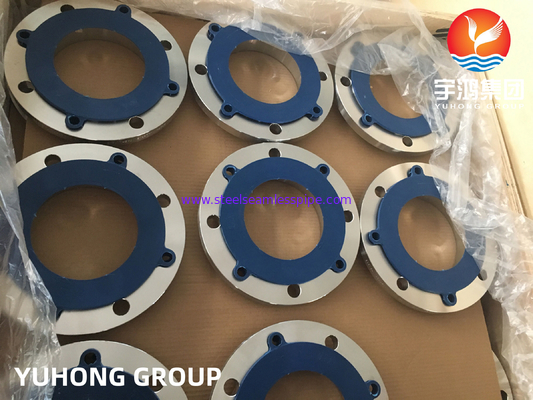

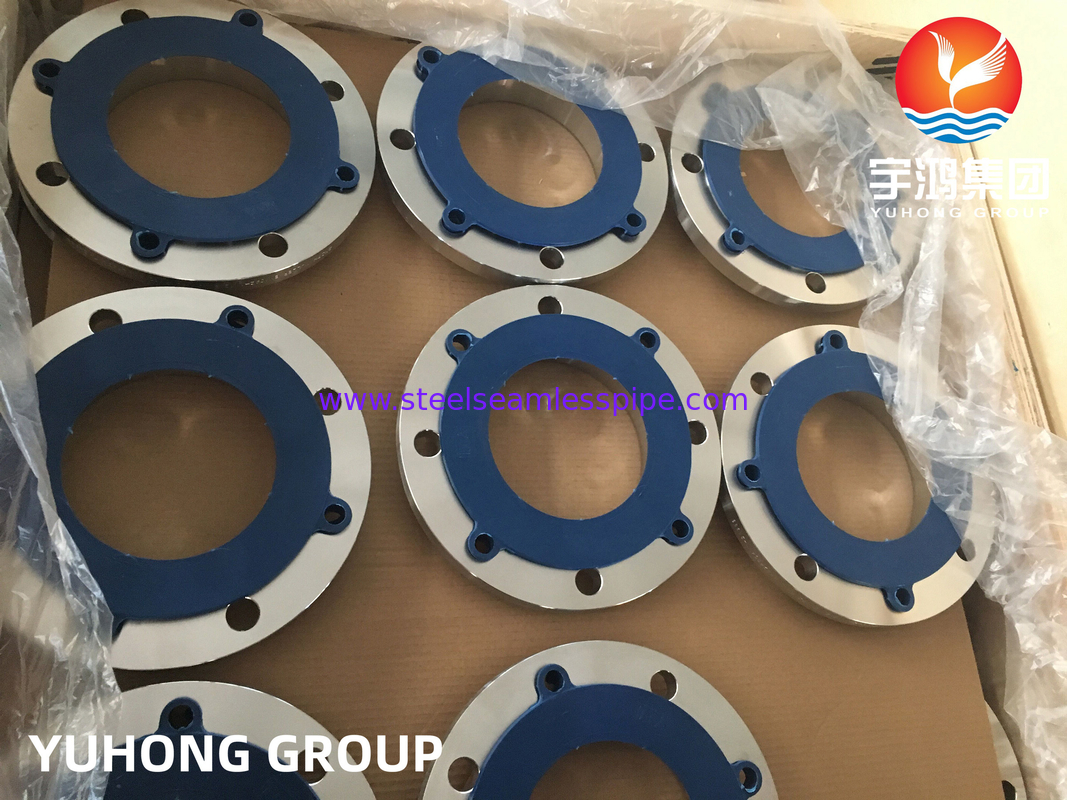

YUHONG Stainless distributes Stainless Steel Flanges including: Slip-Ons, Socket Weld, Blinds, Lap Joints, Threaded and Weld Necks.

Slip-on Flanges

Slip-on Flanges have a lower initial cost than welding neck flanges because they require less accuracy in cutting pipe to length, and they provide a greater ease of alignment in assembly. However, their calculated strength under internal pressure is approximately 2/3's the strength of welding neck flanges, and their life under fatigue is 1/3 shorter. Slip-on Flanges are limited to 1/2" to 2½" sizes in 1500lbs standard.

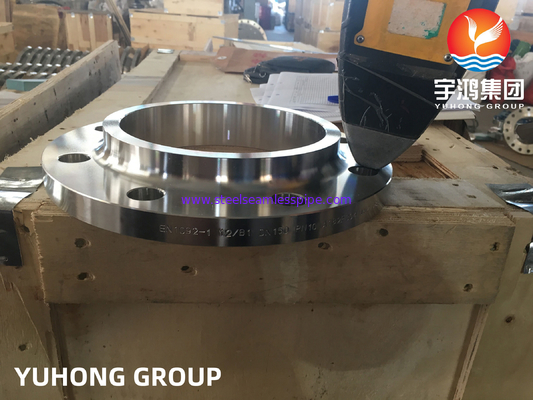

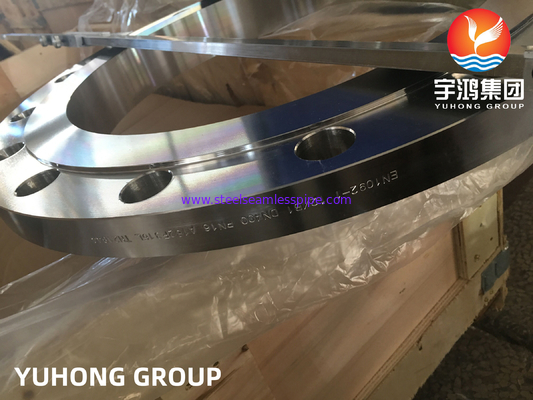

Weld Neck Flanges

Weld Neck Flanges have a long tapered hub and gradual transition of thickness in the region of the butt weld joining them to the pipe. The tapered hub provides important reinforcement to the flange and resistance to dishing. This type of flange is preferred for severe service conditions resulting from high pressure, sub-zero or high temperatures.

Blind Flanges

Blind Flanges are used to blank off the ends of piping, valves and pressure vessel openings. Blind Flanges can handle high stress from internal pressure and bolt loading since the maximum stresses in the blind flange are bending stresses at the center.

Socket Weld Flanges

Socket Weld Flanges were developed for use on small size high pressure piping. With an internal weld, socket weld flanges are stronger and have greater fatigue strength than double welding a slip-on flange. Smooth bore conditions can be easily attained by grinding the internal weld. This flange is commonly used in chemical process piping.

| Grade |

|

C |

Mn |

Si |

P |

S |

Cr |

Mo |

Ni |

N |

| 316L |

Min |

- |

- |

- |

- |

- |

16.0 |

2.00 |

10.0 |

- |

| Max |

0.03 |

2.0 |

0.75 |

0.045 |

0.03 |

18.0 |

3.00 |

14.0 |

0.10 |

| 304 |

Min |

- |

- |

- |

- |

- |

18.0 |

- |

8.0 |

- |

| Max |

0.08 |

2.0 |

0.75 |

0.045 |

0.030 |

20.0 |

- |

10.5 |

0.10 |

| 304L |

Min |

- |

- |

- |

- |

- |

18.0 |

- |

8.0 |

- |

| Max |

0.030 |

2.0 |

0.75 |

0.045 |

0.030 |

20.0 |

- |

12.0 |

0.10

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!