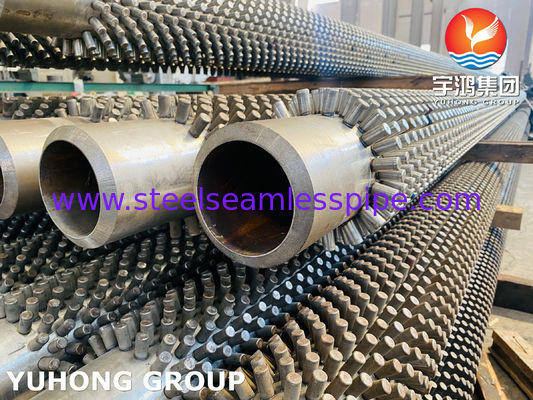

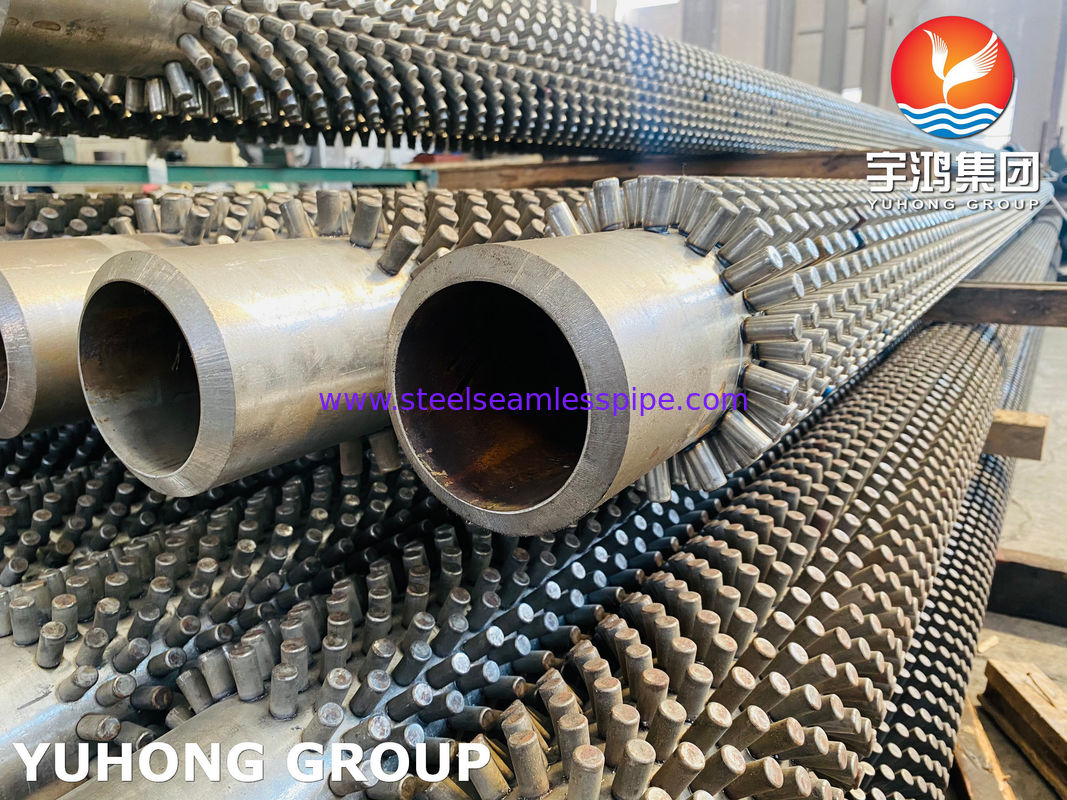

ASTM A312 TP316L Studded Finned Tube For Heat Exchange Systems

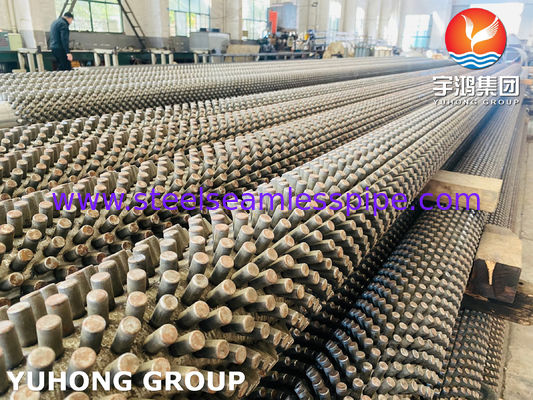

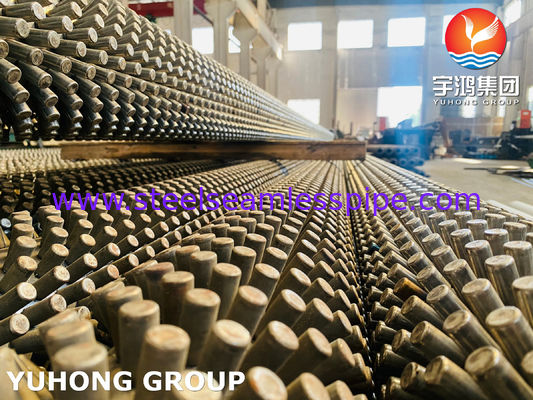

Studded finned tubes are manufactured through resistance welding of studs onto bare tubes. The fins are created by welding fin material, which consists of studs or rods, to the tube base using resistance welding technology.

Manufacturing Process & Advantages

Electricity passes through both the tube and the stud base during welding. The stud shape is specially designed to facilitate the welding process. During fin welding, the stud is mechanically pressed against the tube at the weld point, resulting in an excellent mechanical bond. This type of finned tube performs exceptionally well under high pressure and high temperature conditions.

The mechanical connection is extremely robust, making these tubes suitable for applications with extreme mechanical stresses, such as during machining or cleaning processes.

Applications

These finned tubes are used in finned tube bundles, air coolers, heat exchangers, and similar equipment. They are the preferred choice for industries including petrochemical plants, power generation facilities, chemical processing plants, and steel mills.

Key Features

- Manufacturing Process: Resistance welding

- Tube Bonding: Excellent

- Heat Transfer Efficiency: Excellent

- Mechanical Resistance: Excellent (can withstand frequent high-pressure cleaning, reducing downtime and extending service life)

- Corrosion Protection: Provides excellent protection for the base tube by fully covering it (except for exposed ends)

- Temperature Range: Dependent on material properties of fins (studs) and tubes

Product Range & Capabilities

For applications including heat recovery systems, furnaces, and boilers in refining and petrochemical industries, we supply studded fin tubes, flat tubes, U-tubes, discs, and related components from leading European manufacturers.

Our manufacturing capabilities allow for a wide range of fin configurations, stud specifications, tube sizes, and custom combinations to meet specific client requirements. We deliver products with minimal production issues and reduced equipment testing time.

Technical Specifications

| Particulars |

Range |

| Base Tube Material |

Stainless Steel, Carbon Steel, Alloy Steel, Titanium, Copper, Duplex Stainless Steel, Inconel, etc. |

| Base Tube Outside Diameter |

60 mm to 200 mm |

| Base Tube Thickness |

3 mm to 12.70 mm and above |

| Base Tube Length |

2000 mm minimum to 15000 mm |

| Stud Material |

Carbon Steel / Stainless Steel / Alloy Steel |

| Stud Thickness |

6 mm to 16 mm |

| Stud Density |

15.88 mm or 63 studs per plate per meter (customizable to client requirements) |

| Stud Height |

12.7 mm to 63.5 mm |

| Bare Ends |

As per client requirement |

Studded fin tubes / Stud fin tubes are available with EN 10204 EN 3.1 and EN 3.2 certification. We can arrange third-party inspection by any recognized inspection agency.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!