- YUHONG brand goods have been already exported to more than 85 countries With more than 35 years' experience, because of strict quality control policy, excellent sales service, delivery on time. YUHONG won more and more new clients and got more and more repeat orders from old clients, in YUHONG People's mind: Quality is First Important!

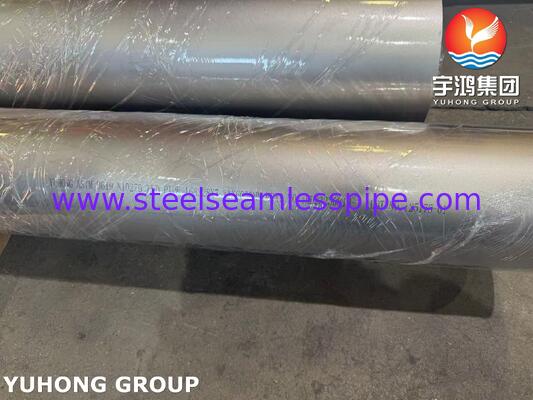

ASTM B619 N10276(C-276 / 2.4819) Welded Nickel Alloy Pipe, Hastelloy Pipe for High Tolerance

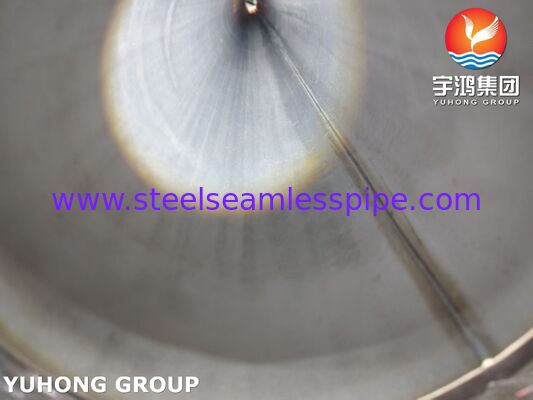

ASTM B619 N10276 Welded Nickel Alloy Pipe is a tubular product manufactured from a nickel-chromium-molybdenum-tungsten, solid-solution strengthened alloy (UNS N10276, commonly known as Hastelloy® C-276, Material Number 2.4819) via an automated welding process. Its defining characteristic is the alloy's near-universal exceptional corrosion resistance, capable of withstanding a wide range of severe corrosive conditions, including oxidizing media, reducing acidic environments, chloride-induced pitting and crevice corrosion, and stress corrosion cracking. The welding process is specifically controlled to ensure that the corrosion resistance of the weld seam and its heat-affected zone (HAZ) is equivalent to that of the base metal, with no susceptibility to sensitization. This pipe is extensively used in critical corrosion conveyance systems where material reliability is paramount, such as in chemical processing, petrochemical, flue gas desulfurization (FGD), pollution control, and marine engineering applications.

- Manufacturing: Typically made from rolled and welded sheet or plate. The weld seam is usually heat-treated (solution annealed) to restore corrosion resistance.

-

Low-Carbon Welded Version: The B619 standard, combined with the C276 chemistry, ensures a low-carbon product. This is crucial to prevent carbide precipitation in the heat-affected zone of the weld, which could become a site for corrosion attack.

| STANDARD |

UNS |

WNR. |

AFNOR |

EN |

JIS |

OR |

GOST |

| Hastelloy C276 |

N10276 |

2.4819 |

- |

NiMo16Cr15W |

NW 0276 |

ЭП760 |

ХН65МВУ |

1.Chemical & Mechanical Properties

| ASTM B619 N10276 Chemical Composition (%) |

| Ni |

Cr |

Mo |

Fe |

W |

C |

Si |

Co |

Mn |

V |

P |

S |

| Rem |

14.5-16.5 |

15.0-17.0 |

4.0-7.0 |

3.0-4.5 |

≤0.010 |

≤0.08 |

≤2.5 |

≤1.0 |

≤0.35 |

≤0.04 |

≤0.03 |

Mechanical Properties

| Density |

Melting Point |

Yield Strength (0.2%Offset) |

Tensile Strength |

Elongation |

| 8.89 g/cm3 |

1370 °C (2500 °F) |

Psi – 52,000 , MPa – 355 |

Psi – 1,15,000 , MPa – 790 |

40 % |

2. Key Adventages

- Unmatched Corrosion Resistance:

It offers exceptional performance in both oxidizing and reducing corrosive environments. It provides effective resistance to a wide range of aggressive media, including sulfuric, hydrochloric, and phosphoric acids, wet chlorine gas, and hypochlorites.

Its high molybdenum content grants exceptional resistance to chloride-induced pitting and crevice corrosion. Furthermore, its low-carbon formulation and balanced chemistry make it highly immune to chloride stress corrosion cracking (SCC), a common failure mode for many stainless steels.

- Optimal Balance of Performance and Economy:

Compared to more expensive exotic alloys (e.g., Titanium, Zirconium, Hastelloy B-series), C276 offers a broader spectrum of corrosion resistance. The welded manufacturing process provides better cost-effectiveness and dimensional flexibility for producing large-diameter, thin-wall, or thick-wall pipes compared to seamless options, making it one of the most cost-efficient solutions for severe corrosion problems.

3. Key Applications

- Digesters and bleach plants in the paper industry.

- Components exposed to sour gas.

- Equipment for flue-gas desulfurisation plants.

- Evaporators, heat exchangers, filters and mixers used in sulfuric acid environments.

- Sulfuric acid reactors.

- Organic chloride process equipment.

- Equipment for processes utilizing halide or acid catalysts.

—————————————————————————————————————————————————————————————————————————

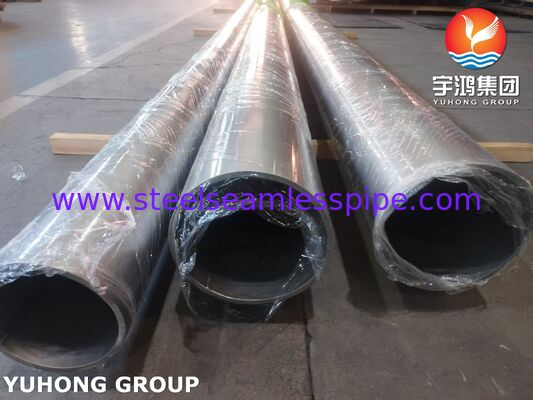

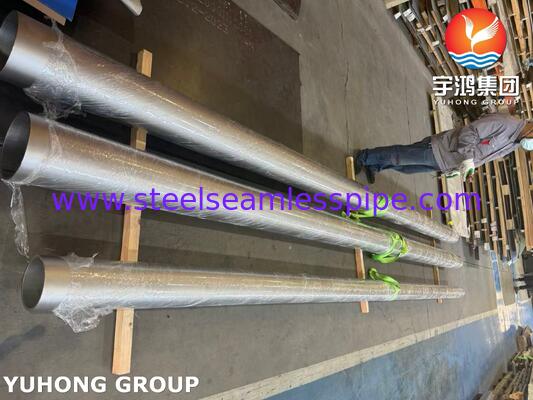

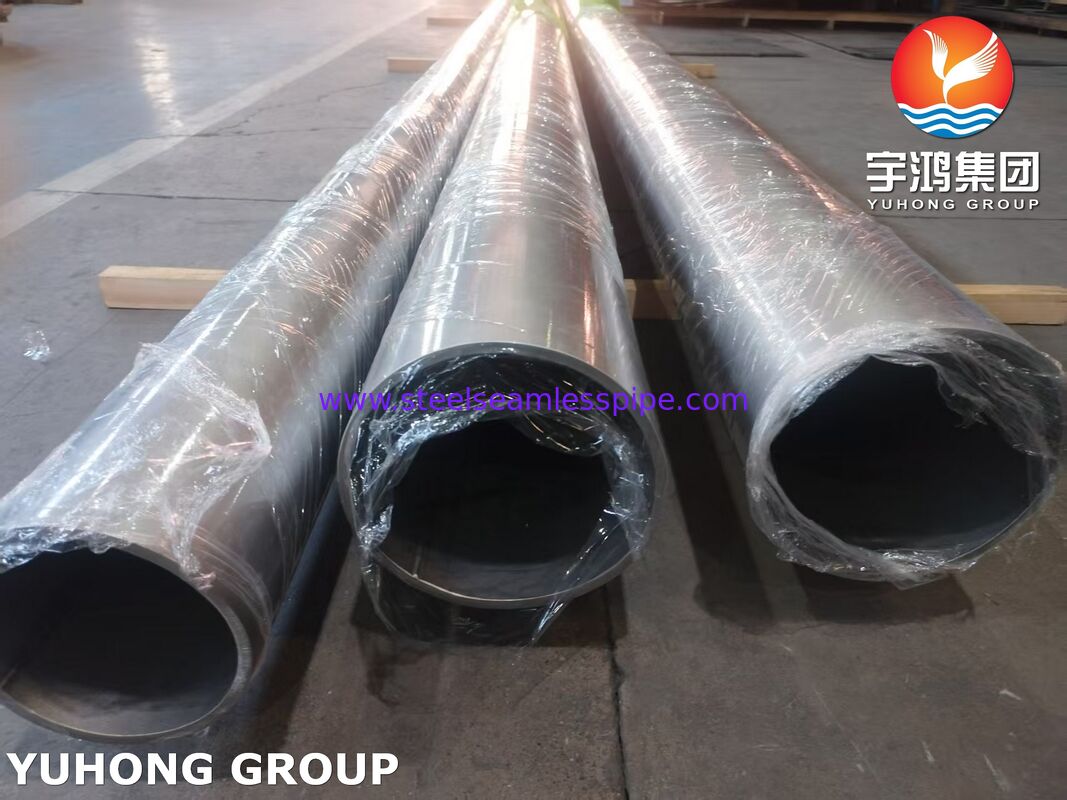

Packing and Shipping:

Product Packaging:

- All pipes are securely packed in wooden boxes or bundles with plastic caps to avoid damage during transit.

- Each box/bundle is strapped with metallic strips for added strength.

- Boxes/bundles are clearly labeled with product details and shipping marks for easy identification.

Shipping:

- We offer worldwide shipping to any destination as per customer requirements.

- We work with trusted shipping companies to ensure timely delivery and e handling of products.

- Customers can choose from various shipping options including air, sea, or land transport.

- Shipping costs may vary depending on the shipping location and mode of transport.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!