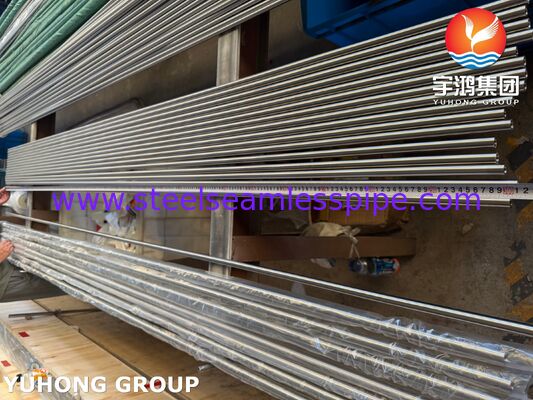

Bright Annealed Stainless Steel Seamless Tube For Pharmaceutical Industry ASTM A269 TP316L

ASTM A269 TP316L(UNS S31603) Bright Annealed(BA) Stainless Steel Seamless Tube is a high-precision, corrosion-resistant tubular product specifically engineered for hygienic and corrosive service environments. It is manufactured without a welded seam, subjected to a controlled annealing process in a protective atmosphere to prevent surface oxidation, and supplied with a smooth, clean interior and exterior surface finish. The ASTM A269 standard specifies the requirements for seamless and welded stainless steel tubing for general corrosion-resistant and low or high-temperature service, while TP316L denotes the specific austenitic stainless steel grade with ultra-low carbon content and molybdenum addition for enhanced corrosion resistance. This stainless steel seamless bright annealed tube’s surface finish is polished and bright annealed . And the polished grade generally includes #180, #320, #400, #600, #800 grit. The primary use of this seamless tube in the biopharmaceutical industry is for process piping systems that handle purified water, water-for-injection (WFI), clean steam, process gases, and sensitive biological fluids where purity, cleanability, and corrosion resistance are paramount.

Different Surface Finishes:

The surface finish, particularly the Internal Surface, is critical for cleanability and preventing bacterial adhesion (biofilm formation).

1. Bright Annealed (BA): The standard finish. Provides a smooth, reflective, passive surface with a typical Ra ≤ 0.5 µm. Suitable for many process applications.

2. Electropolished (EP): An electrochemical process that removes a thin layer of surface material, smoothing micro-peaks and enhancing the passive chromium oxide layer. This results in:

- Superior smoothness: Ra values as low as ≤ 0.25 µm or better.

- Enhanced corrosion resistance: Thicker, more uniform passive layer.

- Improved cleanability: Ultra-smooth surface minimizes particle adhesion and allows easier cleaning and sterilization (CIP/SIP).

- Deburring: Removes microscopic burrs.

BA tubes are often subsequently electropolished for the most critical applications (BA+EP).

Key Features of This Stainless Steel Tube:

- Excellent Corrosion Resistance: Superior to 304/L due to 2-3% Molybdenum, resisting pitting and crevice corrosion from chlorides and process chemicals.

- Hygienic & Cleanable: Seamless, smooth interior prevents entrapment. BA/EP finishes support Sterilization-in-Place (SIP) and Clean-in-Place (CIP).

- Low Carbon Content (≤0.030%): Prevents sensitization, ensuring weld zone corrosion resistance.

- High Purity & Integrity: Seamless construction and controlled manufacturing ensure no contamination.

- Mechanical Properties: Good strength and ductility across a range of temperatures.

- Passive Surface: The inherent chromium oxide layer is stabilized by BA/EP processes.

Different Applications of ASTM A269 TP316L Stainless Steel Tube:

Process Piping: A piping system used for transporting liquid, gas or solid materials in industrial production processes.

- Purified Water (PW) and Water-for-Injection (WFI) distribution loops.

- Clean Steam (Pure Steam) lines for sterilization.

- Process gases (Nitrogen, Oxygen, Compressed Air).

- Product transfer lines for buffers, media, and bulk drug substances.

Bio-Process Equipment:

- Fermenters, bioreactors, and fermenter harvest lines.

- Chromatography skids and holding vessels.

- Filtration systems and ultra-filtration modules.

- Clean Utilities: HVAC ducting in cleanrooms, pharmaceutical grade water systems.

Other Industries with High Purity Needs:

- Food & Beverage: Product lines for dairy, brewery, and high-acid foods.

- Semiconductor: High-purity gas and chemical delivery.

- Chemical Processing: Handling corrosive agents where chloride stress corrosion cracking is a concern.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!